Introduction to the Steel Bar Threading Machine

The steel bar threading machine is an essential tool in the steel processing industry, specifically engineered to create threads on steel bars for various construction projects. This innovative equipment significantly enhances productivity while ensuring precise threading, which is crucial for applications in building construction, roadworks, and bridge development. By incorporating this advanced machinery, construction companies can achieve exceptional results and maintain the structural integrity of their projects.

Key Features and Functions

Commonly known as the steel bar mechanical heat treatment processing technology threading machine, this equipment is packed with advanced features that streamline the threading process. It integrates seamlessly into production lines, delivering impressive efficiency, precision, and energy-saving capabilities. This makes it an indispensable asset for large-scale construction operations.

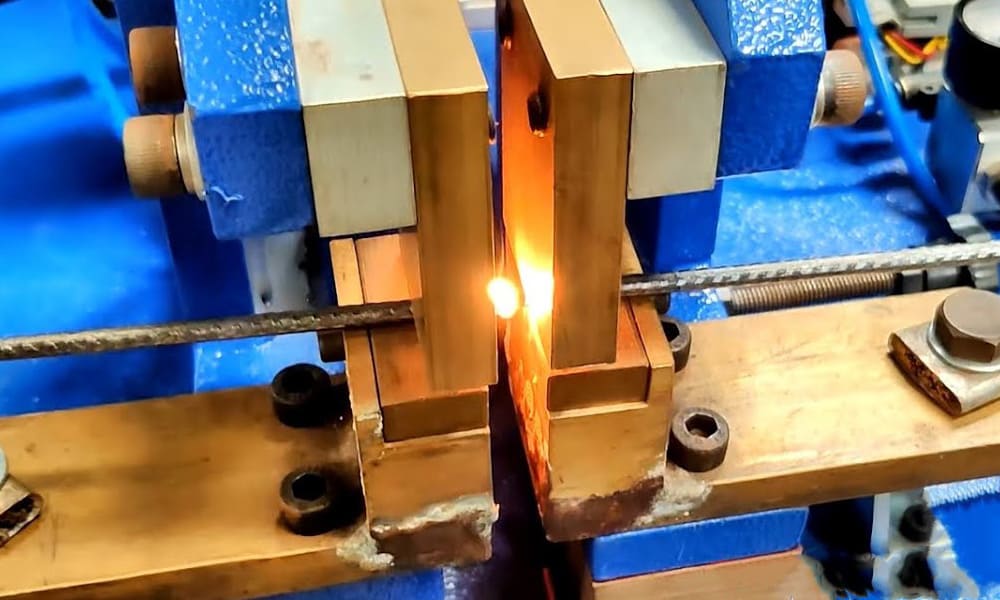

- Operating Principle: The machine operates using a combination of cutting, milling, threading, and feeding systems. It expertly creates threads on both ends of steel bars through precise cutting and tapping procedures, ensuring compliance with stringent specifications and strength requirements necessary for construction.

Benefits of Using a Rebar Threading Machine

- Enhanced Efficiency: The steel bar threading machine greatly increases productivity compared to traditional manual methods. Its automated processes reduce processing time and ensure consistent thread quality, leading to higher output at construction sites.

- Energy Conservation: Equipped with energy-saving features, this machine helps lower operational costs and reduces energy consumption, making it an eco-friendly choice for modern construction projects.

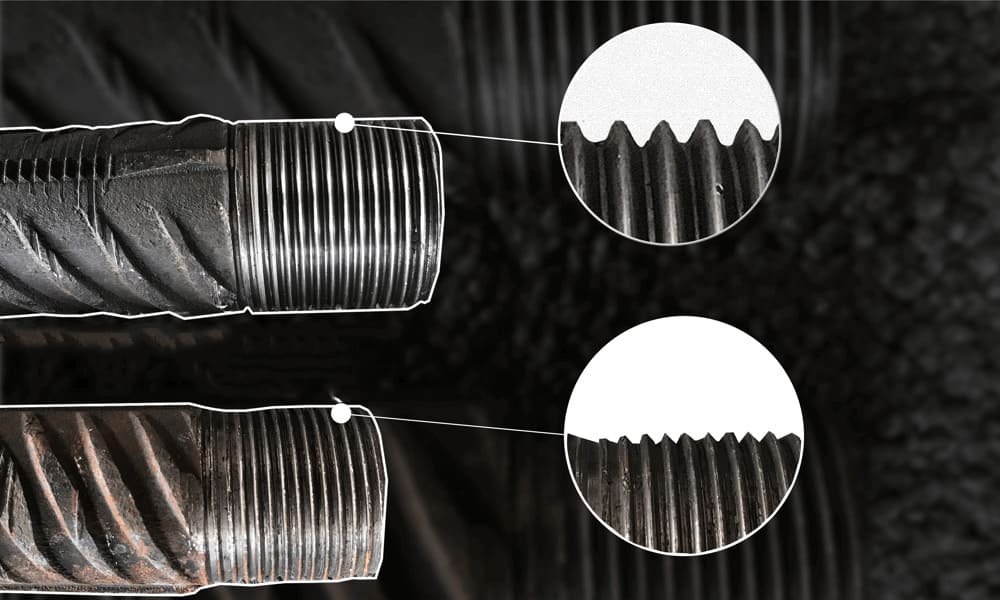

- Precision and Accuracy: The machine guarantees uniform threading on each steel bar, meeting the highest standards for structural strength and durability essential for safe construction.

- User-Friendly Interface: Designed with an intuitive control panel, the machine is easy to operate, allowing users to efficiently manage settings and monitor the threading process.

- Robust Construction: Made from high-quality materials, the steel bar threading machine offers long-lasting durability and reliable performance, even in challenging construction environments.

Applications in Construction

The rebar threading machine is widely utilized in various construction applications, including building construction, roadworks, and bridge projects. Its ability to process high-strength steel bars makes it ideal for projects where precision and stability are paramount. The threaded ends of steel bars can be easily connected using couplers, enhancing the overall structural integrity of the construction.

Conclusion

In conclusion, the steel bar threading machine represents a significant advancement in steel processing technology, offering unmatched efficiency and precision for construction projects. With streamlined operations, energy-saving features, and high accuracy, this machine is an excellent investment for construction companies looking to optimize their workflows and achieve outstanding results. By integrating this advanced equipment, firms can enhance their competitiveness and consistently deliver top-quality outcomes in building, road infrastructure, and bridge development projects.