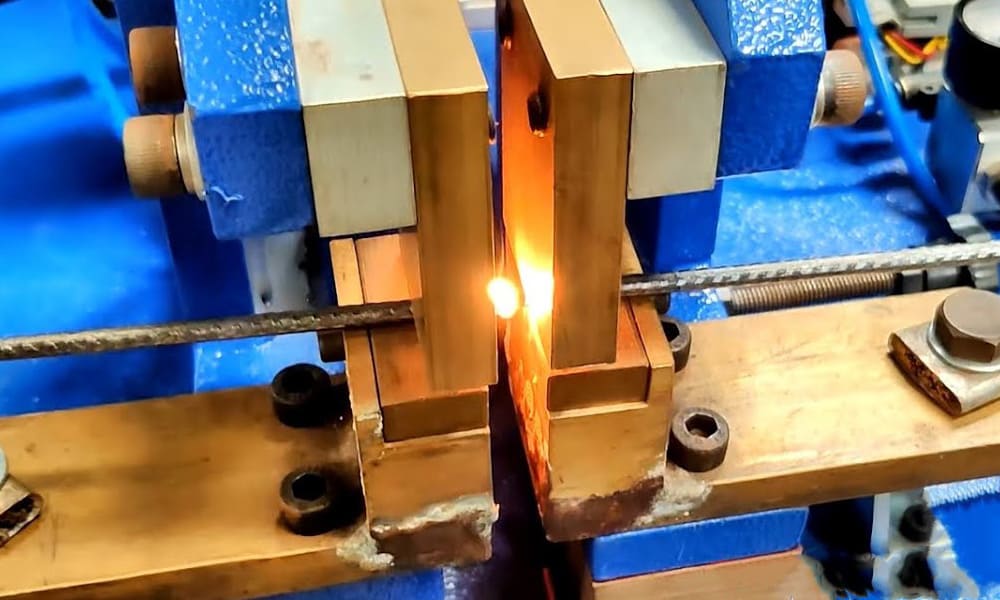

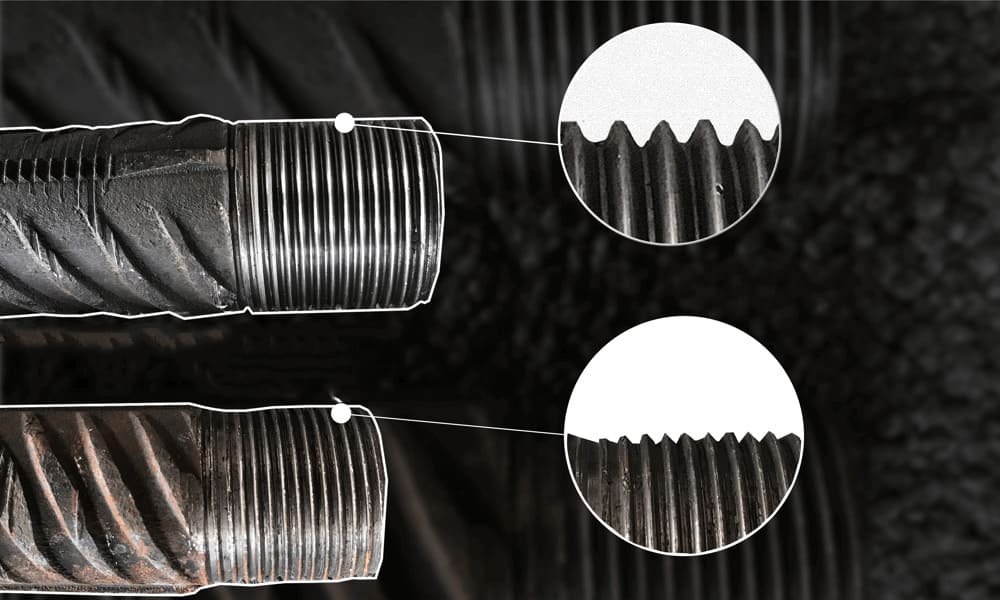

A fully automatic steel bar threading machine, including electric versions, automates the entire process of threading steel bars. This includes automatic clamping, threading, wire withdrawal, and clamp loosening. Operators only need to manage the display screen. These advanced machines, controlled digitally, streamline the threading of prestressed steel bars, completing rib stripping and thread rolling in a single operation. The resulting threads are precise and uniform, capable of handling both positive and reverse threads.

Features of GHM Machinery’s Fully Automatic Steel Bar Threading Machine

GHM Machinery offers state-of-the-art fully automatic steel bar threading machines designed for tough and demanding environments. The operation is entirely screen-based, reducing labor needs and minimizing environmental impact on project timelines. This enhances production efficiency and promotes energy savings, making the process more eco-friendly.

Key features include:

- Automatic Clamping and Threading: Fully digital control allows for hands-free operation, improving safety and efficiency.

- High Precision: The machines produce complete and accurate thread profiles, suitable for various threading requirements.

- Energy-Efficient and Eco-Friendly: Reduced labor and automated processes lead to significant energy and resource savings.

Enhanced Capabilities with Additional Equipment

These machines can be equipped with cold cutting saws, enabling simultaneous cutting and threading of steel bars. This dual functionality outperforms traditional methods where cutting and threading are done separately.

Types of GHM Machinery’s Fully Automatic Steel Bar Threading Machines

GHM Machinery provides two main types of threading machines:

- Pneumatic Fully Automatic Threading Machine: Utilizes air pressure for operation.

- Electric Fully Automatic Threading Machine: Operates using electric power, providing robust and reliable performance.

Evolution from Manual to Fully Automatic

Previously, steel bar thread rolling required manual placement, clamping, and machine movement. The fully automatic electric threading machine addresses these challenges by automating positioning, clamping, and threading functions.

Benefits of Steel Bar Rolling Straight Thread Connection Technology

This technology is essential for both industrial and civil construction, offering several advantages:

- Simplicity and Speed: The process is quick and can be pre-made, reducing construction time.

- Safety and Environmental Benefits: No open flames and minimal pollution.

- Reliability and Continuous Construction: The technology supports uninterrupted construction and saves materials and energy.

- Efficiency: A single worker can connect rebar joints in about a minute using just a wrench, significantly shortening construction periods and promoting industrialized building practices.

GHM Machinery’s fully automatic steel bar threading machines represent the future of efficient, precise, and environmentally friendly construction technology.