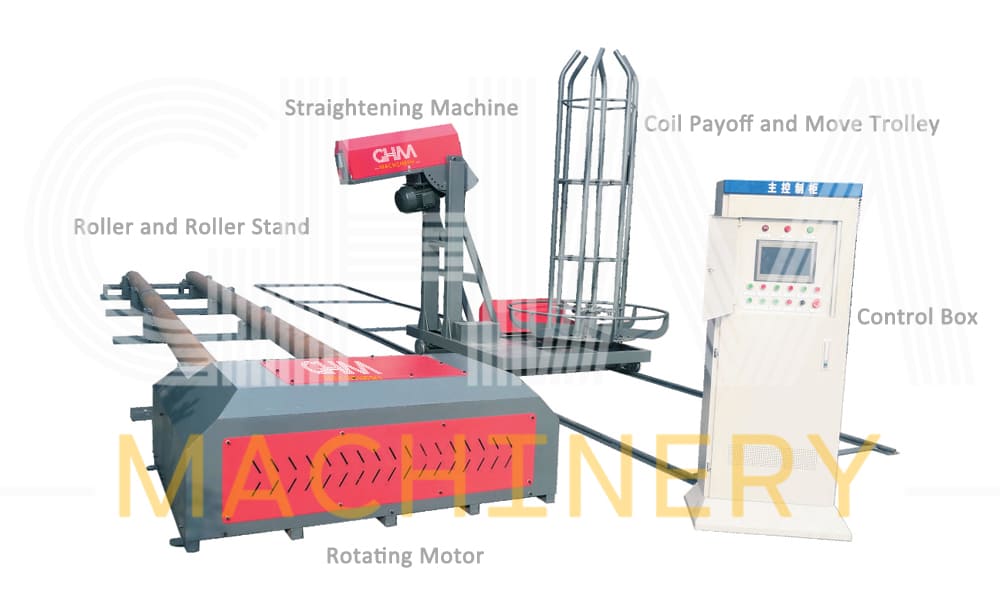

Steel Bar Cage Making Machineis an indispensable tool in steel bar processing, extensively utilized in construction projects due to its efficiency, simplicity, and ease of use. This powerful machinery streamlines the production of steel cages, making it a preferred choice in the industry. Let’s take a closer look at its main components, unique features, and the benefits it offers, spotlighting GHM Machinery as a leading manufacturer.

Components of the Steel Bar Cage Making Machine

The machine consists of two primary systems: the Mechanical Working System and the Welding Control System. Each system plays a vital role in ensuring smooth and precise operation.

- Mechanical Working System:

- Main Drive System:

- Equipped with a frequency conversion speed-regulating motor, it powers the rotation of the main machine, allowing precise winding of the ring bars onto the longitudinal bars.

- Tie System:

- Operated by a traction frequency conversion motor, this system guides the tensioning car linearly using a chain mechanism, ensuring accurate traction and welding of the longitudinal bars.

- Electrode System:

- The pneumatic electrode system automatically adjusts the preload force, providing consistent welding quality and prolonging the lifespan of the electrodes.

- Hydraulic System:

- The hydraulic system is designed to boost force by regulating pressure. It comprises hydraulic transmission and control units, ensuring smooth operations and precise adjustments.

- Main Drive System:

- Welding Control System:

- Welding Control Unit:

- This unit features a fully digital welding controller and proximity switch, allowing for easy adjustments of welding specifications and executing commands with high accuracy.

- Welding Control Main Loop:

- Comprising a welding transformer, thyristor component, copper conductor, and water-cooling system, this system manages the welding current while maintaining optimal temperature to prevent overheating and ensure consistent quality.

- Welding Control Unit:

Product Highlights of the Steel Bar Cage Making Machine

The steel cage winding machine from GHM Machinery offers several advantages that enhance its efficiency and usability in demanding construction environments:

- Fast Production Speed:

- Capable of producing 10-20 sections of steel cages with just 3-6 workers, the machine significantly reduces labor costs and accelerates project timelines.

- Stable Quality Output:

- The machine’s mechanized operations eliminate variability caused by human error, ensuring consistent, high-quality steel cages that meet rigorous standards.

- Wide Scope of Application:

- The machine supports a variety of design requirements for shape, size, model, and length of stirrups, making it suitable for diverse construction needs without compromising on flexibility.

- Ease of Operation:

- With its modular design, the machine is easy to transport, install, and operate, eliminating the need for heavy lifting equipment and minimizing setup time.

- Energy Efficiency:

- The machine operates at less than 15KW total power, and the synchronized systems consume under 5KW during standard operations, making it an energy-efficient solution for large-scale production.

- Resilience to External Conditions:

- The assembly line construction design enables continuous welding and forming operations, even under challenging environmental conditions, ensuring project continuity.

- Technological Advancements:

- Incorporates threaded connection technology, allowing for rapid disassembly and assembly of steel cages, thus improving overall efficiency and facilitating easy adjustments.

Why Choose GHM Machinery?

GHM Machinery is known for its expertise in producing high-quality construction machinery. With a focus on innovative design, durability, and efficiency, their steel cage winding machines are engineered to meet the evolving demands of the construction industry. By choosing GHM Machinery, clients can benefit from:

- Reliable Performance: Consistent output that meets industry standards.

- Advanced Features: Cutting-edge technology for enhanced productivity.

- Expert Support: Professional guidance and customer service to ensure optimal machine utilization.

For inquiries and purchases, GHM Machinery welcomes industry professionals to explore their wide range of construction solutions, ensuring that every project is executed with excellence.