To ensure the safe and efficient operation of Straight Steel Rebar Thread Rolling Machine, it is essential to follow these comprehensive procedures:

1. Straight Steel Rebar Thread Rolling Machine Worker Training and Certification

- Mandatory Training: All operators must complete technical training and pass a skill assessment before operating the machines.

- Fixed Personnel: Teams should consist of fixed personnel to maintain consistency and safety in operations.

2. Equipment Debugging and Testing

- Pre-Production Testing: Thoroughly debug and test the equipment before starting formal production.

- Function Confirmation: Production should commence only after all equipment has been confirmed to be functioning correctly.

3. Steel Bar Cutting

- End Face Preparation: Ensure the end face of the steel bar is perpendicular to its axis and free from imperfections (e.g., horseshoe shapes or arches).

- Straightening Requirement: If the end is not straight, straighten it before cutting.

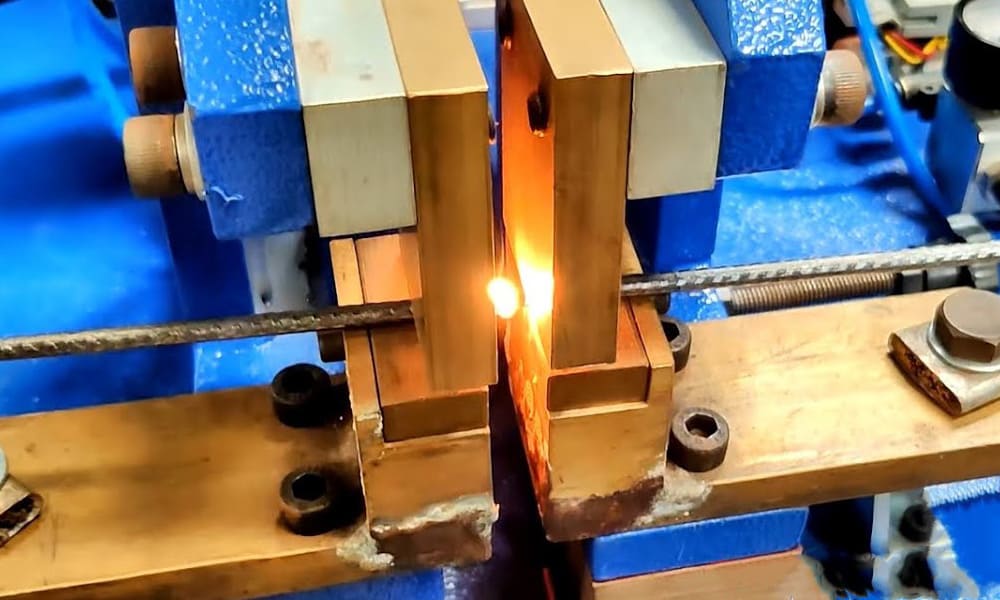

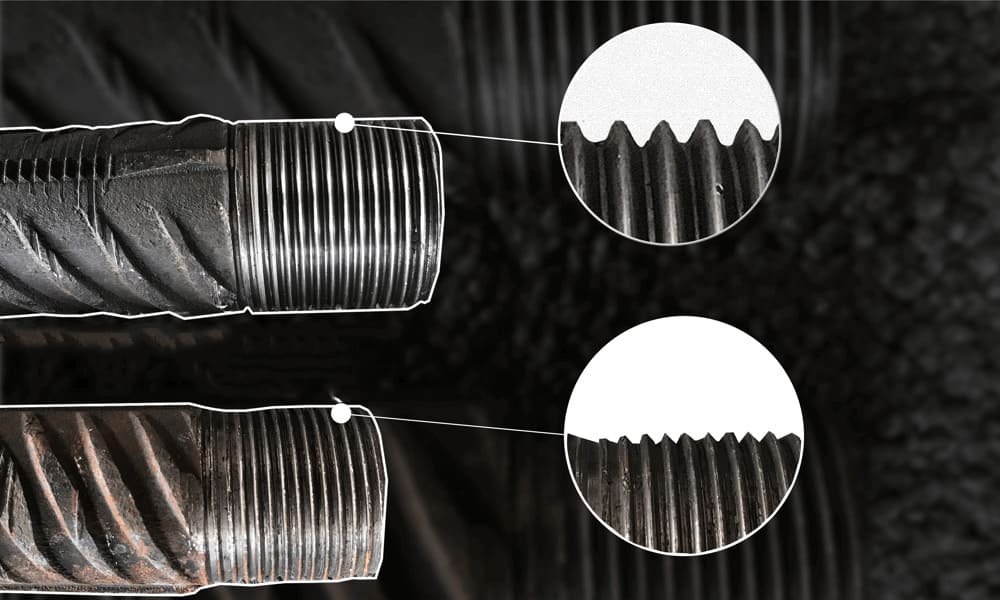

4. Steel Bar Head Roughening

- Roughening Process: Roughen the steel bar head before threading.

- Machine Setup: Reset the roughening machine to zero before starting and ensure the steel bar is correctly inserted and tightened.

- Quality Control: Discard and re-roughen any unqualified roughened heads; avoid roughening the same head more than once.

5. Quality and Safety Checks

- Crack Inspection: Inspect the roughening section for any transverse cracks.

- Threading Method: Use appropriate threading methods and apply water-soluble cutting fluid.

- Cold Weather Precautions: In temperatures below 0°C, implement anti-freezing measures and avoid adding cutting fluid during thread processing.

6. Pre-Shift Equipment Check

- Operational Test: Before each shift, run the machine empty to check its condition.

- Condition Checks: Verify the normal rotation of the machine head, adequacy of cutting fluid, electrical switch sensitivity, screw tightness, and normal sounds from the motor and reducer.

7. Timely Maintenance

- Immediate Repairs: Address any equipment failures immediately; do not operate malfunctioning equipment.

- Dust-Free Maintenance: Perform maintenance on high-pressure oil pumps indoors in a dust-free environment to prevent contamination of the oil system.

8. Post-Shift Maintenance

- Cleaning Procedures: After each shift, clean iron filings from the pier head, fixtures, and molds.

- Fluid Replacement: Clean the machine head and table, replace cutting fluid as needed, and lubricate the guide rod and rotating parts.

9. Training and Authorized Personnel

- Authorized Operators: Only trained personnel are authorized to operate the equipment.

- Electrical Faults: Address electrical faults only by qualified electricians.

10. Personal Protective Equipment (PPE)

- Safety Gear: Operators must wear safety helmets on-site.

- Clothing Precautions: When operating threading machines, gloves are prohibited, and sleeves should be tightly secured with buttons fastened.

11. Compliance with Regulations

- Safety Management: Adhere to all safety management regulations and site-specific rules.

12. Regular Safety Education

- Safety Awareness: Project leaders should conduct regular safety education sessions to enhance safety awareness and inspect for potential hazards.