Operating straight bar thread rolling machine requires adherence to technical procedures and safety protocols to ensure optimal performance and minimize risks. Follow these key practices:

1. Staff Training and Assessment

- Training: Ensure all operators undergo rigorous technical training and skills assessment.

- Consistency: Maintain a consistent team to ensure uniform operation and proficiency.

2. Equipment Debugging and Testing

- Pre-Production: Thoroughly debug and test equipment before starting formal production to confirm proper functionality.

3. Steel Bar Cutting and Straightening

- Cutting: Cut steel bars so that end faces are perpendicular, free of horseshoe shapes or arches.

- Straightening: Straighten any bars with non-perpendicular ends before further processing.

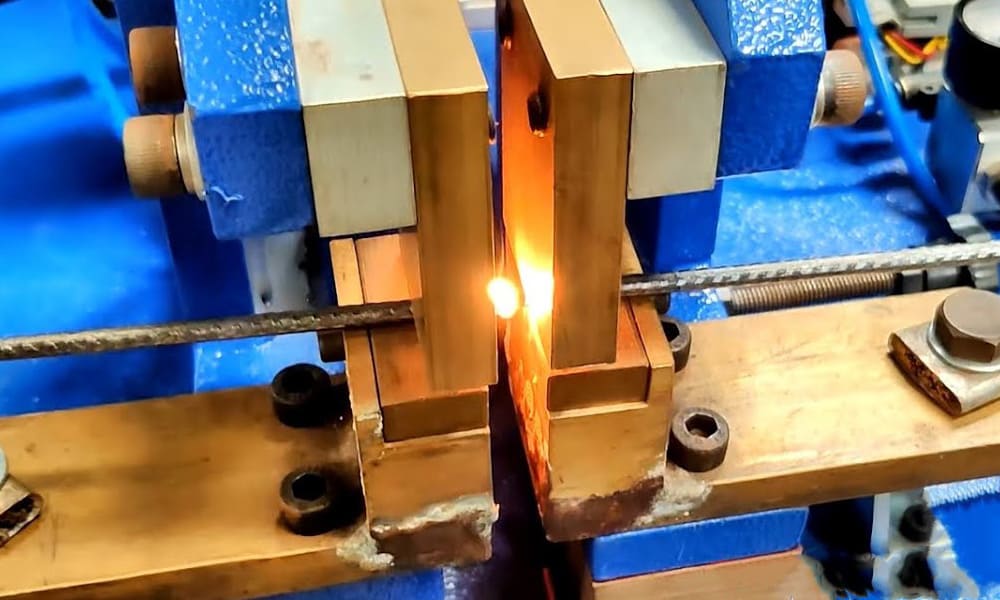

4. Thickening Steel Bar Heads

- Preparation: Appropriately thicken steel bar heads before installing steel wires.

5. Pier Preparation

- Machine Zero Position: Ensure the pier roughening machine is set to zero.

- Insertion: Insert steel bars straight into the pier to maintain the reserved length.

6. Quality Control

- Unqualified Heads: Cut off and re-pierce unqualified pier heads; avoid re-threading.

7. Crack Prevention

- Thick Sections: Ensure thick steel pier sections are free from transverse cracks.

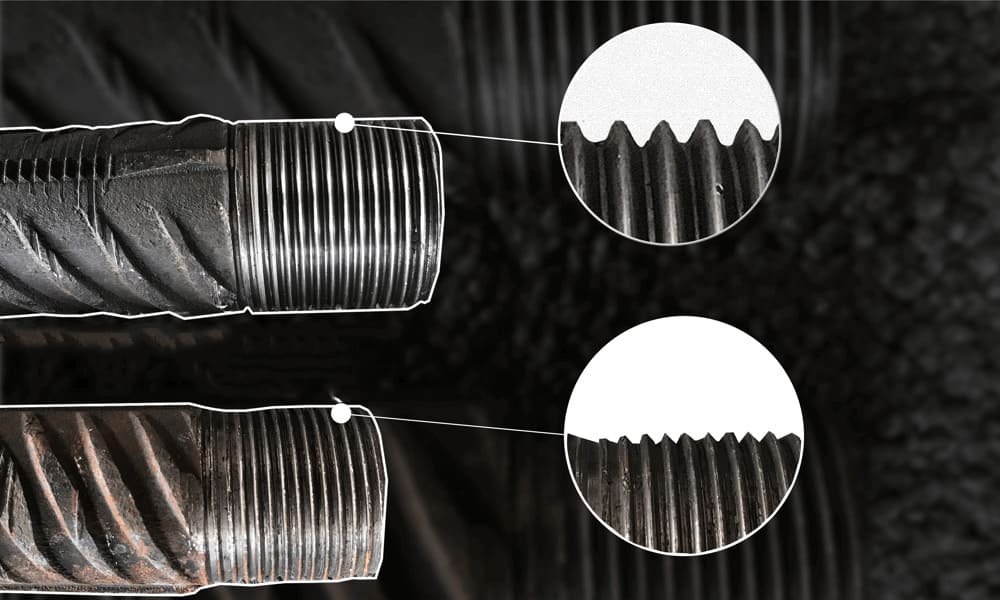

8. Thread Processing

- Method: Use the thread threading method for processing thick steel bar sections.

9. Cutting Fluid Usage

- Fluid: Use water-soluble cutting fluid for steel wire end processing.

- Antifreeze: Add antifreeze measures below 0°C.

- Avoidance: Do not use cutting fluid during thread processing.

10. Pre-Shift Inspection

- Checklist: Run the machine empty before each shift. Check:

- Equipment condition

- Rotation of the machine head

- Cutting fluid levels

- Electrical switch sensitivity

- Screw tightness

- Motor and reducer sounds

11. Equipment Maintenance

- Malfunctions: Address and eliminate equipment malfunctions promptly. Do not operate faulty equipment.

12. Oil Pump Maintenance

- Conditions: Perform maintenance of high-pressure oil pumps indoors in dust-free conditions to prevent oil system contamination.

13. Post-Shift Cleaning

- Cleaning: Clean iron filings from pier heads, fixtures, and molds. Clean the machine head and table, lubricate guide rods and rotating parts.

14. Trained Personnel Only

- Restriction: Allow only trained personnel to operate the equipment; untrained individuals are strictly prohibited.

15. Electrical Safety

- Handling: Non-electricians should not handle electrical failures in equipment.

16. Personal Protective Equipment (PPE)

- Helmets: Operators must wear safety helmets on construction sites at all times.

17. Clothing Safety

- Attire: Operators should not wear gloves. Ensure sleeves are tied tightly and clothes buttons are fastened.

18. Adherence to Regulations

- Compliance: Follow safety management regulations and on-site construction unit rules at all times.

19. Safety Education

- Training: Conduct regular safety education sessions for operators to enhance safety awareness and promptly address safety hazards.

By adhering to these practices, operators can ensure the safe and efficient operation of straight bar thread rolling machine while upholding high standards of production quality.