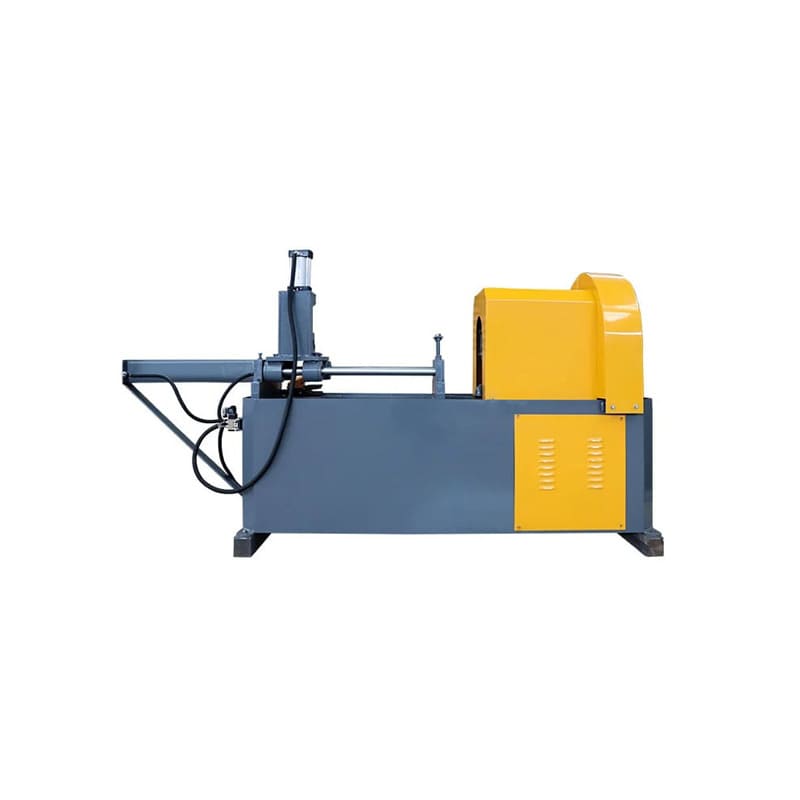

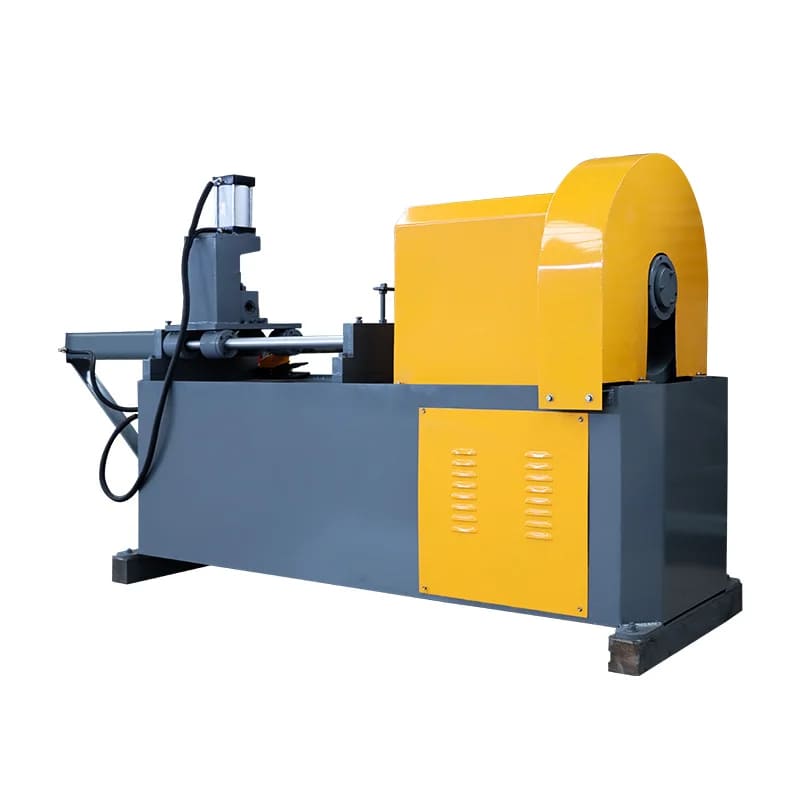

Pipe Tapering Machine is used for automatic processing of advanced small catheter tapered tips. It has the characteristics of low noise, easy operation, high output and stable performance. The workpiece forming time is short, the efficiency is high, the processing surface is smooth, and the workpiece has no scars. It is equipped with a closed-circuit circulation lubrication system to ensure the normal operation of the machine for a long time. The machine mold can be easily replaced. With the cooperation of the corresponding mold, it can process metal pipes of different shapes to meet different needs.

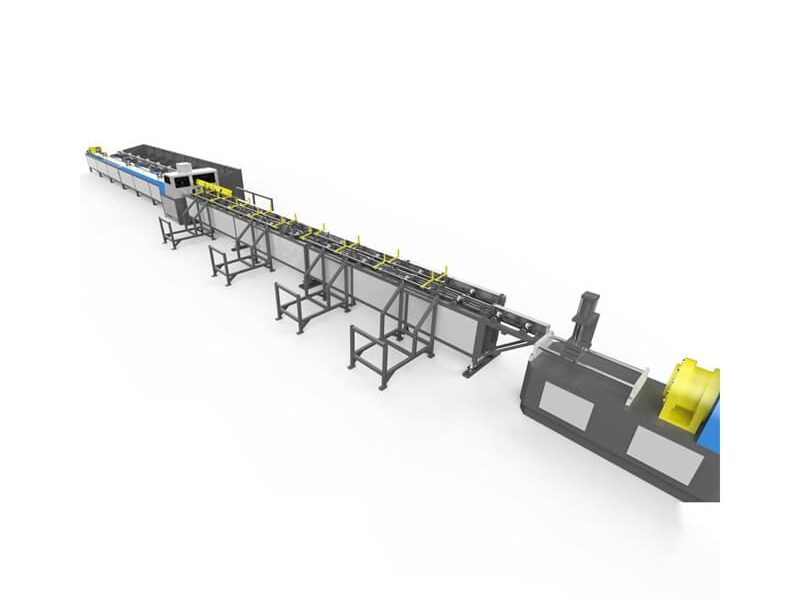

This machine is an automated high-speed punching machine operated by one person. It has fast punching speed, convenient mold replacement and simple positioning. It is the safest and most reliable punching equipment in the industry. According to customer needs, pipe lengths from 2m to 6m can be designed, and various pipe punching machines, fully automatic punching machines, and fully automatic tip reduction machines can be produced and customized. Our highlights are that the program is highly intelligent and user-friendly, and the hole spacing accuracy is guaranteed to be ±0.1mm. The mold is durable.

Advantages of Pipe Tapering Machine:

1. Save manpower: the equipment automatically runs and feeds materials, and automatically calculates time.

2. Save calculation time: The computer has its own memory system that can store multiple sets of memory data.

3. Save a lot of positioning time: pneumatic clamping, strong, no deviation.

4. Save mold changing time: use quick-changing mold structure.

5. Improve production efficiency: Compared with ordinary punch machines, CNC punch machines can improve production efficiency by 60 to 80 times/minute.

6. Improved safety factor: production personnel can operate off-machine, thus minimizing safety accidents.

7. The punch machine comes with a high-speed air cooling system to better solve the problem of oil pipe motor heating.

Instructions of Pipe Tapering Machine:

1. Place the unit on a flat ground indoors with a reliable ground (or zero connection).

2. Inject anti-wear hydraulic oil of brand L-HM46# into the oil tank, and fill the oil level with hydraulic oil to the top of the liquid level gauge.

3. Equip a water tank, install a water pump, and connect water pipes.

4. Check whether the guide sleeve on the front side of the material rack, the heating copper pipe and the feed port of the rack are in line, that is, to ensure smooth feeding during operation.

5. Check whether there are any abnormalities in the circuit and foot switch in the electric control box. If no abnormalities are found in the circuit, connect the power cord of the host.

6. Start the water pump first to ensure that the water circulation is normal, that is, the water shortage indicator light on the electric control box does not light up.

7. Rotate the power adjustment button to adjust the input current.

8. Turn on the timer and adjust the heating time. Generally, the greater the current, the shorter the heating time. (Heating time is usually about 4 seconds)

9. Start the oil pump and ensure normal circulation of the oil pump oil circuit.