Operating a steel bar bending machine requires strict adherence to safety guidelines to protect operators and ensure efficient machine performance. Here are the recommended safety procedures:

Installation and Power Supply

- Grounding: Ensure the machine body is properly grounded.

- Power Supply: Do not connect the power supply directly to the button. Install an iron shell switch to control the power supply.

Pre-Operation Checks

- Component Verification: Ensure all machine parts are complete and in good condition.

- Gear Selection: Confirm that the moving gear matches the diameter of the steel bar to be bent.

- Gear Meshing: Check the gear meshing clearance and ensure the fixed iron wedge is secure.

- Turntable Direction: Verify that the turntable direction aligns with the forward and reverse switch directions.

- Lubrication: Add lubricating grease as per regulations.

- Electrical Inspection: Check insulation and grounding wires for damage or looseness.

- Trial Operation: Conduct a trial operation and proceed only if the machine operates correctly.

Operation Procedures

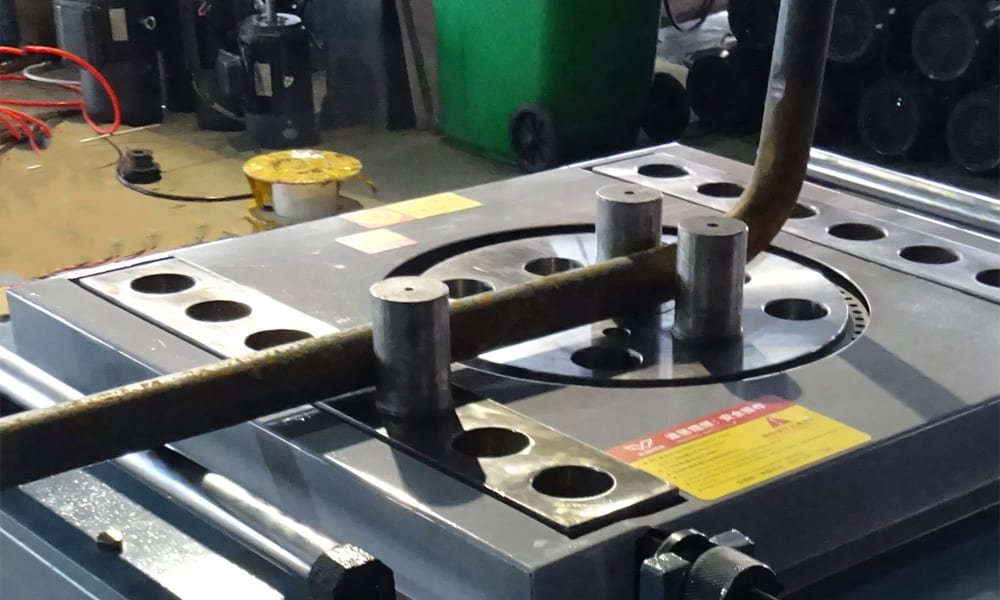

- Steel Bar Placement: Firmly place the end of the steel bar in the gap of the fixed hoe head on the turntable.

- Secure the Bar: Ensure the other end is close to the fixed hoe head of the machine body and pressed tightly with one hand.

- Hoe Head Installation: Verify that the hoe head is correctly installed to block the steel bar before starting the machine.

Replacing the Fixed Hoe Head

- Machine Stop: Only replace the fixed hoe head after the machine has completely stopped.

Bending Specifications

- Diameter Limits: Do not bend steel bars or hooks for lifting rigging that exceed the diameter specified on the machine nameplate.

- Protective Gear: Wear protective glasses when bending steel bars that are not cold-drawn or are rusted.

- Special Steel Bars: For non-ordinary steel bars like low-alloy steel, adjust the maximum limit diameter according to the machine nameplate regulations.

Speed Gear Installation

- Gear Selection:

- Ordinary Steel Bars (≤18 mm): Install fast gears.

- Steel Bars (18-24 mm): Use medium-speed gears.

- Steel Bars (>25 mm): Use slow gears.

Turntable Operation

- Reverse Operation: Reverse the turntable only after the previous turn has completely stopped.

- Switching Gears: Pause at the middle stop gear before switching to reverse gear.

- Machine Issues: If the machine jams, the disc vibrates, or the motor overheats beyond nameplate regulations, immediately power off and stop the machine for maintenance.

Safety Zone

- Operational Safety: Do not stand within the rotation radius of the bent steel bar or on the unsteady side of the machine body.

- Product Stacking: Neatly stack bent semi-finished products with hooks facing downwards.

Handling Long Steel Bars

- Assistance: Assign a dedicated person to assist with long steel bars.

- Coordination: The assisting personnel should move according to the operator’s instructions and avoid arbitrary pushing.

Post-Operation Cleanup

- Worksite Cleaning: Clean the workplace and machine body after work.

- Rust Removal: Blow off rust accumulated in the seam pit using a manual blower; do not use fingers to remove rust.

By adhering to these detailed safety procedures, operators can minimize risks and ensure both safe and efficient operation of the steel bar bending machine.