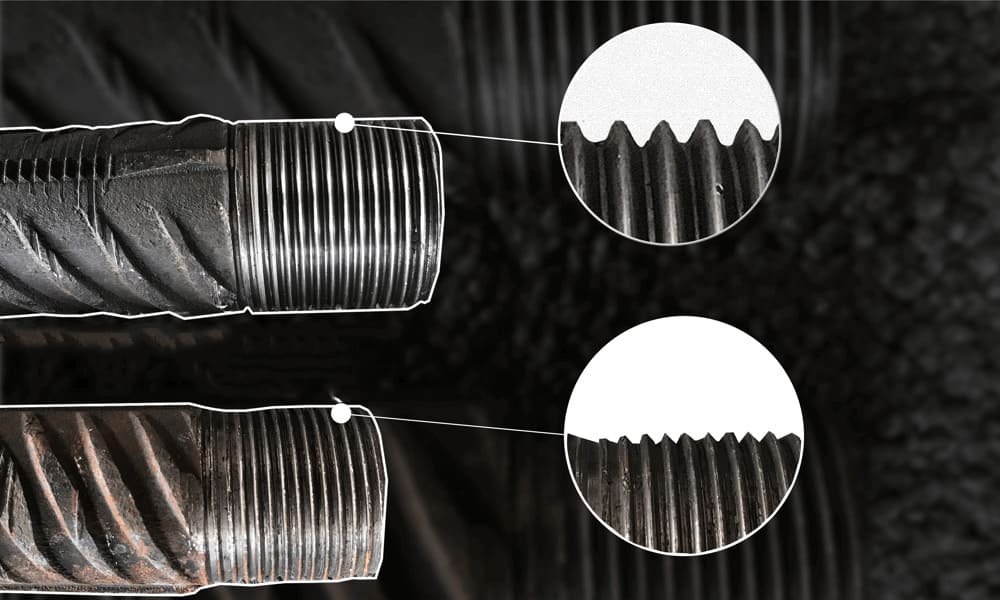

Ensure there is ample space around the cutting machine for steel bar stacking to avoid clutter. Always check that rotating parts are equipped with protective covers to prevent accidents. Regularly inspect the blade for cracks and make sure the fixing screws are tightened securely. When cutting, never hold both ends of the steel bar; only grip it from the side. Maintain a firm hold on the bar, and if you feel pressure from the upper blade, apply additional force to prevent the bar from tilting and causing injury.

Avoid cutting steel bars that exceed the machine’s diameter specifications or are braised. For multiple bars, adjust the blade and cross-section accordingly to prevent mishaps. Use a high-hardness blade when cutting low-alloy steel bars. Always ensure that your hand holding the bar is at least 40 cm long, and keep a safe distance of 15 cm between your hand and the blade.

When handling long steel bars, have a dedicated assistant follow your instructions to avoid dragging the bars. Never clean debris near the blade with your hands while the machine is operating, and keep the work area free of idle personnel. If you notice any issues such as a skewed blade, immediately power off the machine for maintenance. By following these guidelines, you ensure both safety and optimal performance of your steel bar cutting machine.