Rebar Cutter & Bender: Essential Equipment for Steel Reinforcement Projects

Introduction

Rebar Cutter & Bender, In the world of construction and civil engineering, reinforcing steel bars (rebar) are indispensable for strengthening concrete structures. To cut and shape these bars accurately, professionals turn to specialized equipment—rebar cutters and benders. These tools are vital for achieving precision, efficiency, and safety when preparing rebar for foundations, columns, beams, walls, and more.

What Is a Rebar Cutter and Bender?

A rebar cutter and bender is a tool or machine used to:

-

Cut rebar to specific lengths

-

Bend rebar into required angles (e.g., 45°, 90°, U-hooks, stirrups)

-

Process different bar diameters, typically from #3 (10mm) to #8 (25mm) or larger in industrial models

These machines are available in various formats, ranging from manual hand tools to fully automated, CNC-controlled systems.

Types of Rebar Cutters and Benders

1. Manual Rebar Cutters & Benders

-

Operated by hand, including lever-type benders and bolt cutters

-

Best suited for small-scale jobs or remote locations without electricity

-

Low cost, but physically demanding and slower

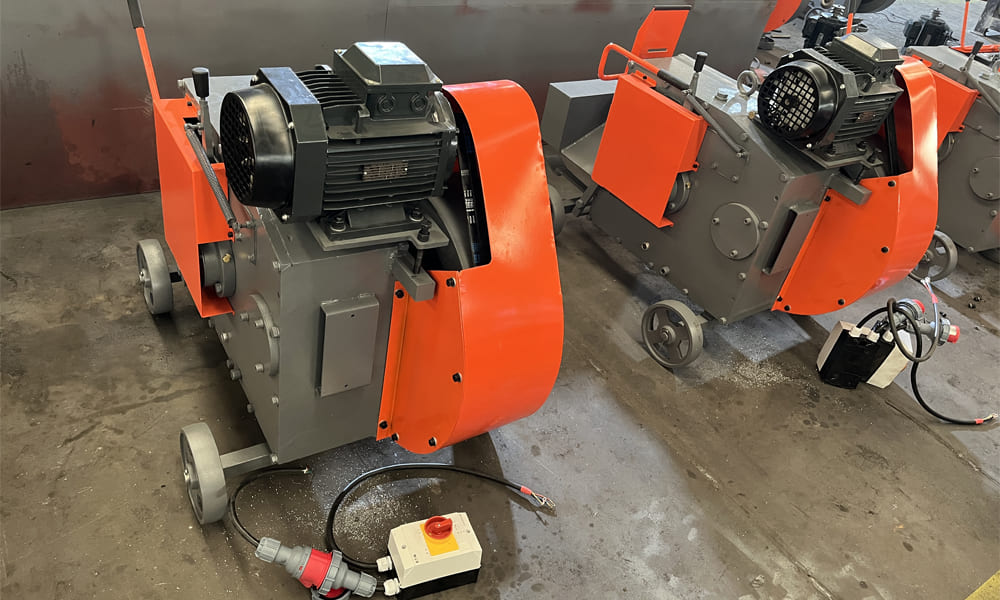

2. Electric & Hydraulic Models

-

Available as portable or stationary units

-

Offer faster operation and can handle larger diameters (up to 40mm or more)

-

Ideal for medium-sized construction sites

3. CNC Automated Rebar Processors

-

Fully automatic machines with computerized control

-

Provide high-speed, high-precision cutting and bending

-

Widely used in precast concrete factories and large infrastructure projects

Key Features to Consider

When selecting a rebar cutter and bender, look for the following:

✔ Processing Capacity – Maximum rebar diameter it can handle

✔ Power Source – Choose from manual, electric, hydraulic, or pneumatic

✔ Portability – Wheeled or compact models for easy transport on job sites

✔ Durability – Robust construction, preferably heavy-duty steel

✔ Safety – Includes blade guards, emergency stops, overload protection

Applications in Construction

Rebar cutters and benders are used across a wide range of construction applications:

-

Foundations & Slabs – Cutting and shaping rebar for footings and bases

-

Columns & Beams – Preparing stirrups and rebar cages

-

Walls – Custom bends for structural wall reinforcement

-

Bridges & Infrastructure – Heavy-duty processing of large-diameter bars

Safety Guidelines for Operation

To ensure safe and effective use of rebar cutting and bending tools:

-

Wear appropriate PPE (gloves, safety glasses)

-

Secure the bar firmly before cutting or bending

-

Do not exceed the machine’s rated capacity

-

Perform routine maintenance, especially on blades and hydraulics

-

Always follow the manufacturer’s instructions and safety protocols

Future of Rebar Processing Technology

The industry continues to evolve with innovative advancements:

-

Robotic Bending Systems – Automated units for large-scale rebar processing

-

IoT Integration – Real-time machine monitoring and predictive maintenance

-

AI Software – Optimized cutting and bending plans to reduce material waste

Conclusion

A reliable rebar cutter and bender is an essential tool for any construction project that involves reinforced concrete. From manual tools to high-tech automated systems, these machines enhance productivity, accuracy, and workplace safety. As construction technology advances, rebar processing will become even more efficient and intelligent—empowering professionals to build faster and smarter.