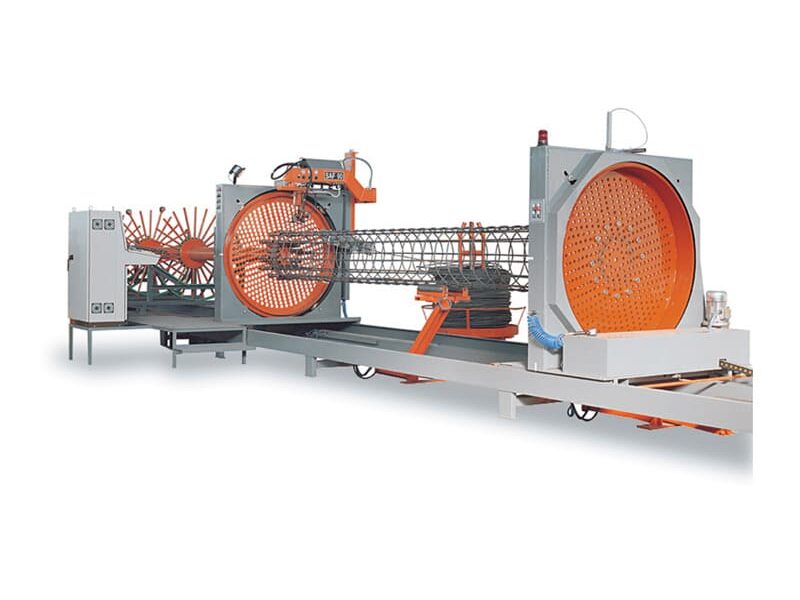

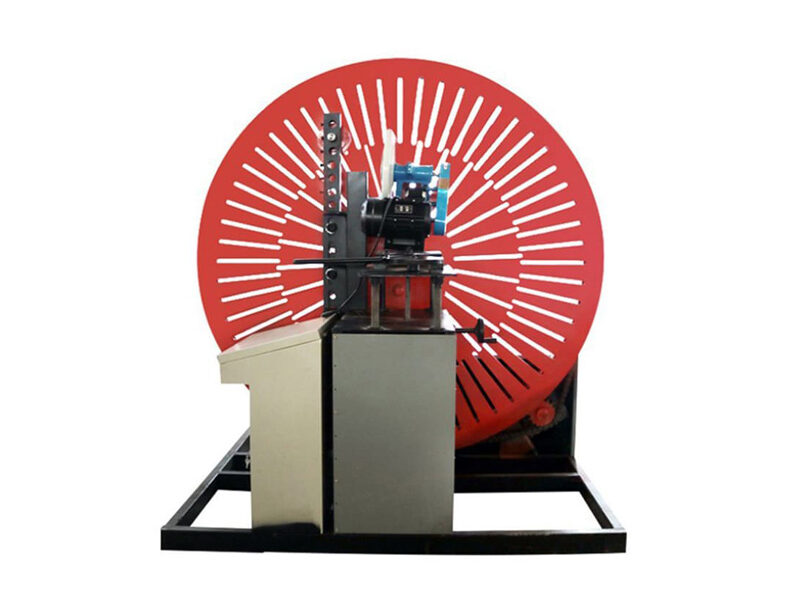

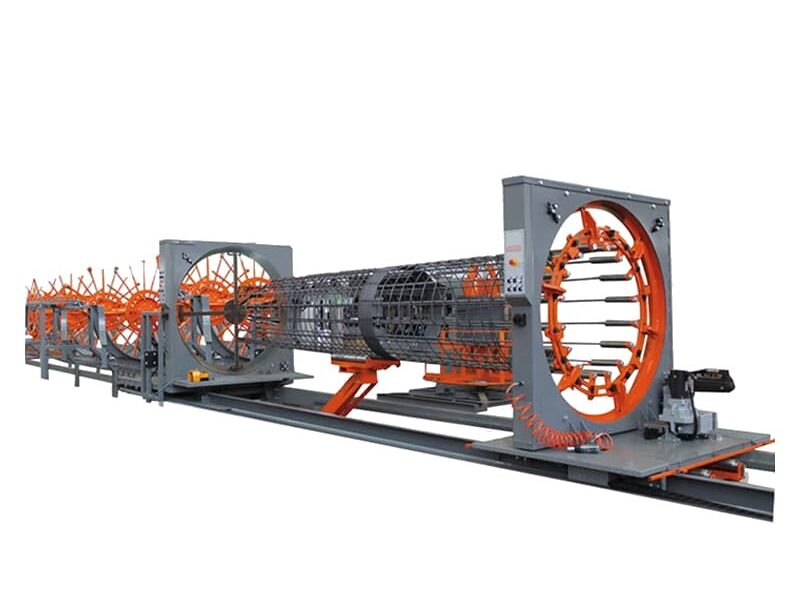

Steel bar cage making machine is mainly composed of the trolley part (including the steel receiving disc, the line straightener, and the track), the power cabinet (numerical control memory operation parameters), and the transmission structure (motor, rolling cage support). It is suitable for bending processing of main skeleton steel bars in large-scale engineering concrete structures such as high-rise buildings, highways, high-speed railways, and large bridges.

|

Model

|

AC-3000(Configured according to basic model)

|

|

Cage Diameter

|

Φ600-Φ3000mm

|

|

Cage Length

|

Length up to 30m(can be customized on demand)

|

|

Winding Speed

|

0-15.4m/min

|

|

Car Speed

|

0-1.38m/min

|

|

Iron Bar Motor

|

Y90l-4 power 4kw

|

|

Trolley Motor

|

Y90l-4 power 4kw

|

|

Total Weight

|

4500kg

|

|

Main Machine Dimensions

|

13*1.8*0.8m

|

|

Overall Dimensions Of Trolley

|

15*1.3*1.5m

|

Steel bar Cage Making Machine Poducts Features

1, Using numerical control technology, the winding speed is stable, the spacing is uniform, and the quality is stable.

2, Adopting modular design, each component can be quickly disassembled, moved, and transported conveniently and quickly

3, The diameter of the rebar cage can be adjusted, and the length can be customized to meet the requirements of various main reinforcement stirrup quantities, models, sizes and lengths

4, Simple operation, simple training of workers, can control the operation, save labor, a group of 2-3 people can complete the overall operation of the equipment

5, The power is small, the total function is less than 10KW

6, The electric control box and the remote control have dual control functions, making the control operation flexible and convenient.

7, The trolley can synchronize two winding ribs, and the host has a memory function, which can adjust and store operating parameters at any time

8, Stirrups are tightened without overlap, which saves 15% of materials compared with manual work and reduces construction costs.