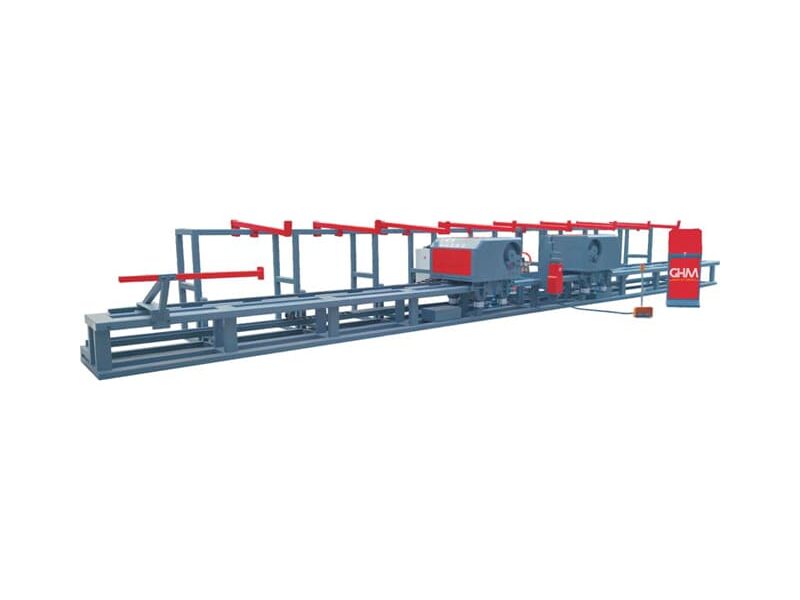

SGW6-16 Automatic Stirrup Bending Machine is a cutting-edge solution for steel bar processing, designed to deliver both efficiency and precision. This fully automated machine handles cold and hot rolled high-strength wire rod steel bars with ease, integrating steel bar straightening, measurement, bidirectional bending, and shearing into one streamlined process.

| Traction Speed | 100m/min | Bend Direction | Clockwise + anticlockwise |

| Bend Speed | 1100°/s | Bend Angle | ±180° |

| Angle Error | ±1° | Single Wire | 6-16mm |

| Length Error | ±1mm | Double Wire | 6-13mm |

| Rebar Shape | Total Power | 68kw | |

| Power Consumption | 17kw/h | Machine Rotation | 45°(90°-135°) |

| Weight | 5000kg | Dimension | 9500*5350*2700mm |

Automatic Stirrup Bending Machine Key Advantages:

- High Automation: SGW6-16 significantly boosts production efficiency compared to traditional models, allowing for faster and more reliable operations.

- Stable Quality: It maintains high-quality results without needing to adjust the steel bar diameter, ensuring consistent construction standards.

- Energy Efficiency: Designed to be energy-efficient, this machine reduces power consumption, making it a cost-effective choice.

- Low Noise: Operates quietly, meeting workplace noise level requirements and creating a more comfortable working environment.

- No Hydraulic Oil: It eliminates the need for hydraulic oil, reducing pollution and simplifying maintenance.

- Reliable Components: Assembled with high-quality imported parts, it offers dependable performance and requires minimal maintenance.

- Easy Part Replacement: Components like cutting knives and bending center shafts are easy to replace, streamlining maintenance tasks.

- User-Friendly Interface: The machine features a graphical interface that is easy to understand, allowing operators to quickly learn and operate the machine with minimal technical expertise.

Technical Advantages:

1. Automatic wire feeding system (CNC)

2. Mobile air compressor design ensures better cooling effect and is easy to transport and install.

3. Split, multi-blade design (patented) to reduce consumption costs.

4. Large storage capacity, can save 500 of processing geometry, high degree of automation.

5. Automatic double-wire feeding system, high processing efficiency.

6. High-power feeding motor to ensure bending accuracy.

7. Intelligent fault identification alarm system maintenance is more convenient.

8. Aerodynamic design observation door, easy to adjust and maintain, higher safety and speed.

9. Heavy-duty design wire plane, equipped with brake and buffer device to prevent messy wire caused by downtime.

10. High-quality special materials and high processing make the straightening wheel, traction wheel, metering wheel, longer service life and have operating costs.

11. Touch screen console, simple operation and faster speed.

12. High efficiency and precise processing accuracy.