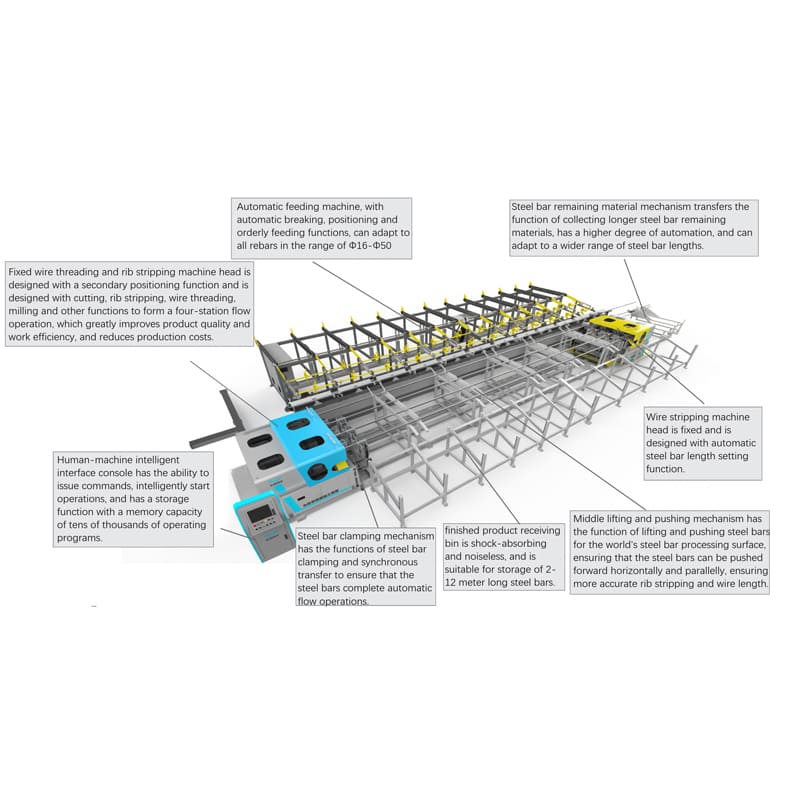

Intelligent Operation

CNC Rebar Threading Line is equipped with a Programmable Logic Controller (PLC) and a user-friendly touch screen interface, making it fully automated and easy to operate by a single person.

High Efficiency and Low Cost

This advanced system can automatically process entire bundles of raw steel bars, eliminating the need for manual feeding. It features a two-speed rolling process that allows for both high and low-speed operations. With a high-quality milling and grinding head designed for low-speed rolling, the machine includes a rapid wire withdrawal mechanism for high-speed operation, effectively removing the need for reverse wire withdrawal. The CNC line operates 1.5 times more efficiently than traditional production lines, as it performs sawing, rib stripping, threading, and polishing processes simultaneously. This design achieves a production capacity of 1,920 steel wire ends per 8-hour shift, equivalent to the output of seven workers using conventional methods.

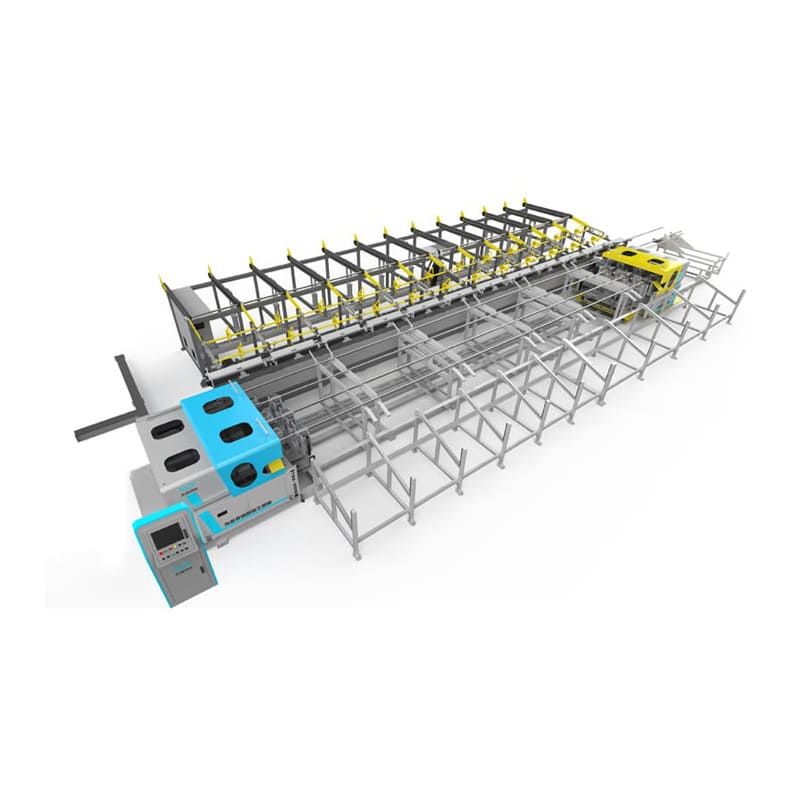

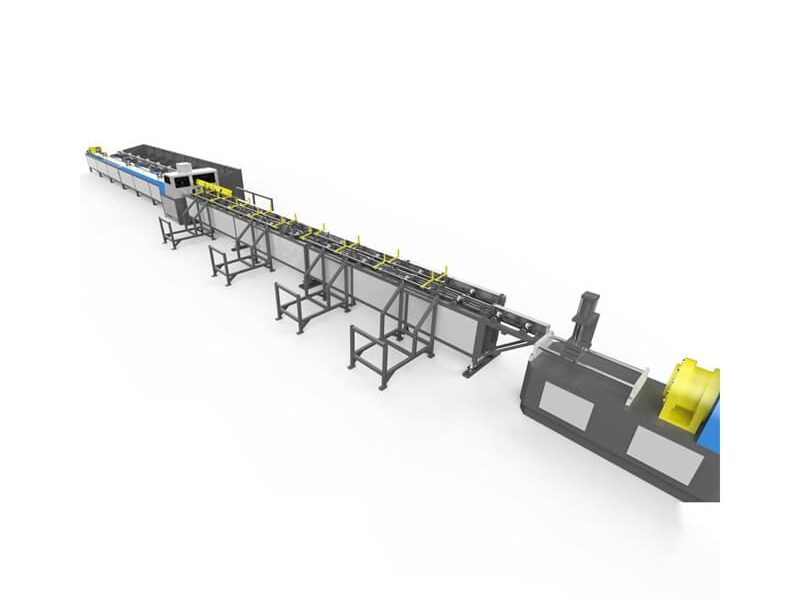

Compact Footprint

With a significantly reduced space requirement of 16m x 8m, this Rebar Threading Line takes up less area than conventional systems (which require 30m x 8m), leading to lower site costs.

Easy Thread Rolling Wheel Replacement

The machine allows for quick replacement of the thread rolling wheel by simply withdrawing the adjustment sleeve. This process takes just 10 minutes, minimizing downtime.

Improved Steel Bar Transfer

The horizontal transfer method employed in this line prevents damage to wire buds and reduces the time needed for steel bar transfers.

Low Maintenance Costs

The design features fewer wearing parts, resulting in lower maintenance costs for the machine and increased operational efficiency.

Information Management

The production line supports a Manufacturing Execution System (MES) for remote transmission of on-site data, including details on steel bar processing, quality, progress, and equipment status. This capability allows for real-time monitoring and management from a control center, enhancing overall production efficiency.