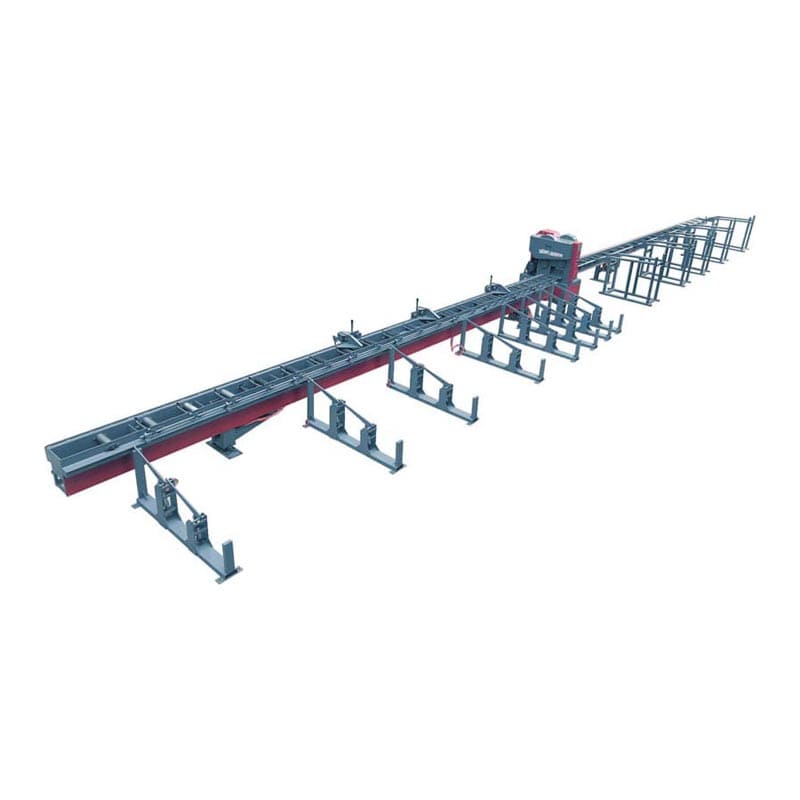

500/800 Rebar Cutting Production Line is designed for high-speed and accurate cutting of steel bars, making it ideal for large-scale construction and manufacturing projects. With cutting speeds ranging from 6 to 10 seconds per cut and a length range of 2 to 12 meters, it offers a balance of speed and precision.

| Feed Speed(m/min) | 40-60 | |||||||

| Cut Length(mm) | 700-12000 | |||||||

| Cut Tolerance(mm) | ±5 | |||||||

| Cut Speed(time/min) | 30 | |||||||

| Blade Width(mm) | 260 | |||||||

| Mini Cut Length Manually(mm) | 10 | |||||||

| Mini Cut Length Automatic(mm) | 700 | |||||||

| Bar Diameter(mm) | φ10-40mm | |||||||

| Power(kw) | 47KW | |||||||

| Size(L*W*H) | 26000*4500*1500 | |||||||

| Cutting Pieces | ||||||||

| Diameter(mm) | 16 | 20 | 22 | 25 | 28 | 32 | 38 | 40 |

| (pieces) | 13 | 10 | 8 | 5 | 3 | 3 | 1 | 1 |

Key Features:

- High-Speed Cutting: Achieves a cutting speed of 6-10 seconds per cut, providing neat and clean shearing results for steel bars of various lengths.

- Wide Cutting Range: Capable of cutting steel bars from 2m to 12m in length, with a maximum incision width of 600mm and an effective processing width of 450-500mm, allowing simultaneous processing of multiple bars.

- Fast and Accurate Material Handling: The transmission speed of 0.8-0.9m/s ensures quick and precise transport of raw materials, enhancing overall productivity.

- Millimeter-Level Accuracy: Shearing length is accurate to the millimeter, ensuring consistent quality and minimal material waste.

Enhanced Production Capacity:

- Capable of handling dozens of steel bars in a single operation.

- Features a two-way unloading system and a two-level storage bin, allowing for separate storage of different product specifications, improving production efficiency and organization.

Reliable Clamping and Automation:

- Uses a combination of hydraulic and pneumatic tightening methods to ensure firm and secure clamping during operations.

- Can seamlessly connect with downstream threading or bending production lines, enabling automated production and reducing manual intervention.

User-Friendly Operation and Maintenance:

- The human-machine interface (HMI) displays troubleshooting prompts, making it easy to identify and resolve issues.

- Equipped with sound and light alerts for material change, preventing downtime and improving equipment utilization.

Servo Fixed Length and Efficient Shearing:

- Servo-driven fixed length system combined with an automatic turning conveyor line allows for precise positioning and easy adjustments.

- Compact hydraulic shearing machine design ensures high efficiency, while movable joints reduce shear vibration and noise, enhancing safety.

Advanced Electric Control System:

- The electric control cabinet is equipped with comprehensive functions, offering an intuitive interface and an appealing appearance, ensuring smooth and reliable machine operations.

With its cutting-edge technology and advanced automation features, the 500/800 Rebar Cutting Production Line is an excellent solution for high-volume steel bar processing, providing reliability, efficiency, and precision in every cut.