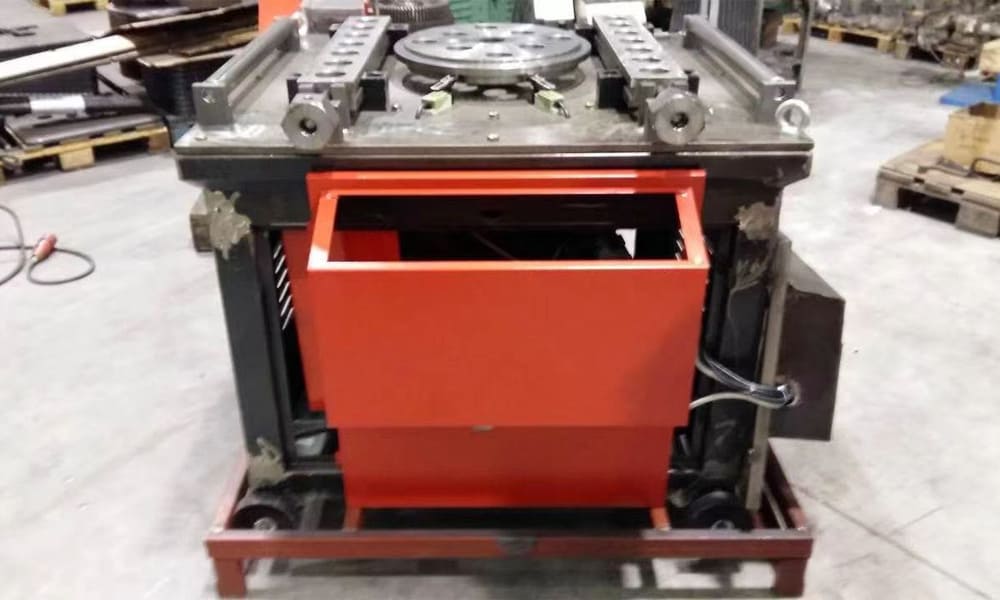

A gear-type steel bar bend machine is an advanced, high-performance solution for bending steel bars with precision. This modernized machine incorporates gear transmission for improved efficiency, replacing traditional worm gear systems. It’s equipped with essential components, each contributing to its superior operation.

Key Components:

- Frame: Provides structural integrity and stability to the machine.

- Motor: Powers the working disk, ensuring smooth bending operations.

- Gear Reducer: Ensures efficient torque conversion and speed regulation, replacing outdated worm gear systems.

- Working Mechanism: Features adjustable insertion seats and a rotating working disk for bending steel bars into various shapes and angles.

- Electrical Control System: Oversees machine operations with features like automatic angle control, braking, and safety mechanisms.

Key Innovations:

- Automatic Angle Control Mechanism: Enhances precision by allowing for preselected bending angles, ensuring accurate bends for different steel bar specifications.

- Brake Device: Ensures immediate stopping of the motor to prevent over-bending or damage to the steel bars, improving safety and efficiency.

How It Works: The Gear-Type Steel Bar Bend Machine

- Motor Activation: A motor equipped with a braking system powers the working disk, initiating the bending process.

- Adjustable Insertion Seats: These seats, adjusted via a handwheel, accommodate steel bars of varying diameters, offering flexibility for different project needs.

- Angle Control: The angle preselection mechanism works with limit pins of different lengths to precisely control the bending angle.

Bending Process:

- The steel bar is placed on the working disk.

- As the disk rotates, the steel bar bends around the insertion seat to the preselected angle.

- Once the bar reaches the preset angle, the limit pin engages the travel switch, halting the motor and reversing the disk, returning it to its starting position.

Advanced Electrical Control System:

- Inching and Automatic Modes: Allows for both manual and automatic operation.

- Two-Way Control: Bends bars in both directions, enhancing operational flexibility.

- Instant Braking: Ensures immediate stops, enhancing safety and precision.

- Emergency Stop and Short-Circuit Protection: Provides safeguards against unexpected failures, ensuring safe operation.

- Motor Overheating Protection: Automatically stops the machine if the motor overheats, preventing damage and prolonging machine life.