Operating a rebar straightening machine requires careful adherence to safety and operational guidelines to ensure efficiency and safety. Here are the recommended procedures:

- Selection of Equipment Settings:

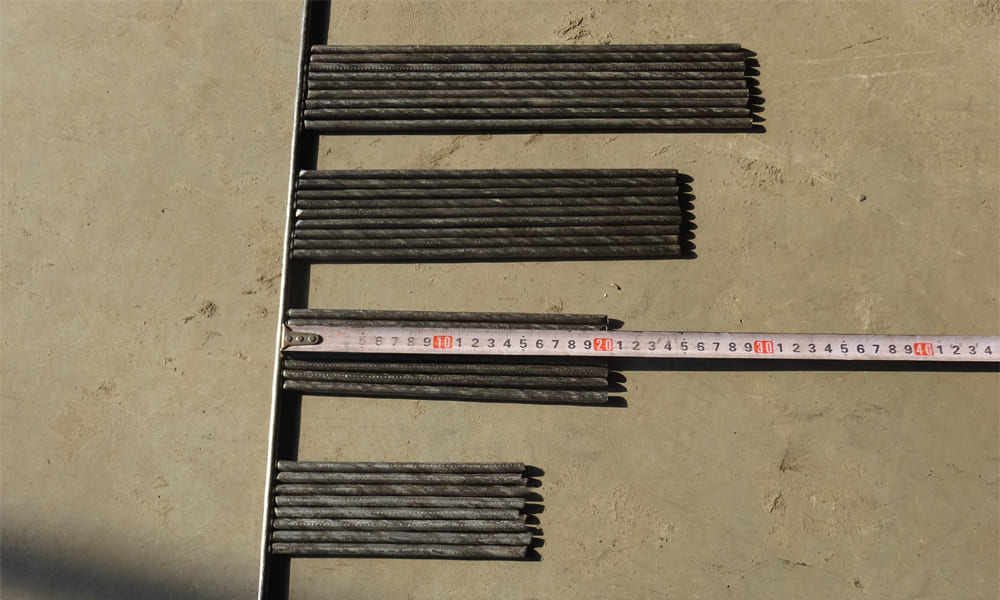

- Choose the appropriate straightening block, traction wheel groove, and transmission speed based on the diameter of the steel bar.

- Ensure the hole diameter of the straightening block is 2-5mm larger than the steel bar diameter, and the traction wheel groove width matches the steel bar diameter.

- Adjustment of Straightening Blocks:

- The straightening cylinder typically includes five blocks. Position the first and fifth blocks on the center line, while the middle three can be offset.

- Start with a 3mm offset for initial adjustments. Increase gradually until the steel bar straightens effectively without excessive bending.

- Verification of Steel Bar Length:

- After cutting three or four steel bars, stop the machine to verify the length.

- Adjust the limit switch or fixed length plate if there is any deviation until the desired length is achieved.

- Preparation for Straightening:

- Place a 1-meter steel bar in front of the guide tube.

- Ensure each coil of steel bars passes through the steel pipe first, then through the guide tube and straightening tube to prevent ejection and potential injuries.

- Safety Precautions:

- Do not insert steel bars before fixing the straightening blocks and covering protective covers to prevent accidents.

- Avoid operating the machine with objects stacked on it to prevent items from falling into the machine during operation.

- Maintain a safe distance from the rollers when loading steel bars and refrain from adjusting the rollers during operation. Never operate the machine while wearing gloves.

- Handling Steel Bars:

- Stay clear of the machine when steel bars are reaching the end of straightening to prevent injuries from swinging bars.

- Process steel bars shorter than 2m or with a diameter exceeding 9mm at lower speeds for safety and effective straightening.

By following these operational procedures meticulously, operators can ensure the efficient and safe operation of the rebar straightening machine, minimizing risks and optimizing productivity.