Proper maintenance of the CNC steel bar sawing and polishing production line ensures optimal performance, extends equipment lifespan, and enhances safety. Below is a detailed guide on maintaining the sawing, threading, and polishing production line.

Introduction to Maintenance Matters

Daily Maintenance Tasks

1.Check Screws:

-

- Inspect all screws in the sawing, threading, grinding, and connecting parts daily to ensure they are not loose.

2.Oil Leaks:

-

- Verify whether the reducer is leaking oil. Address any leaks promptly to prevent equipment damage.

3.Emulsion Levels:

-

- Check if the sawing and threading machines need emulsion and refill as necessary.

Regular Maintenance Tasks

1.Air Compressor Replacement:

-

- Replace the air compressor every 2000-5000 hours. This applies to chain saw machines as well.

2.Gear Oil Replacement:

-

- Replace the gear oil in the reducer of the sawing machine every 5000 hours.

- Check the chain screws for tightness and ensure the motor and shift chain interface are correctly aligned after each shift.

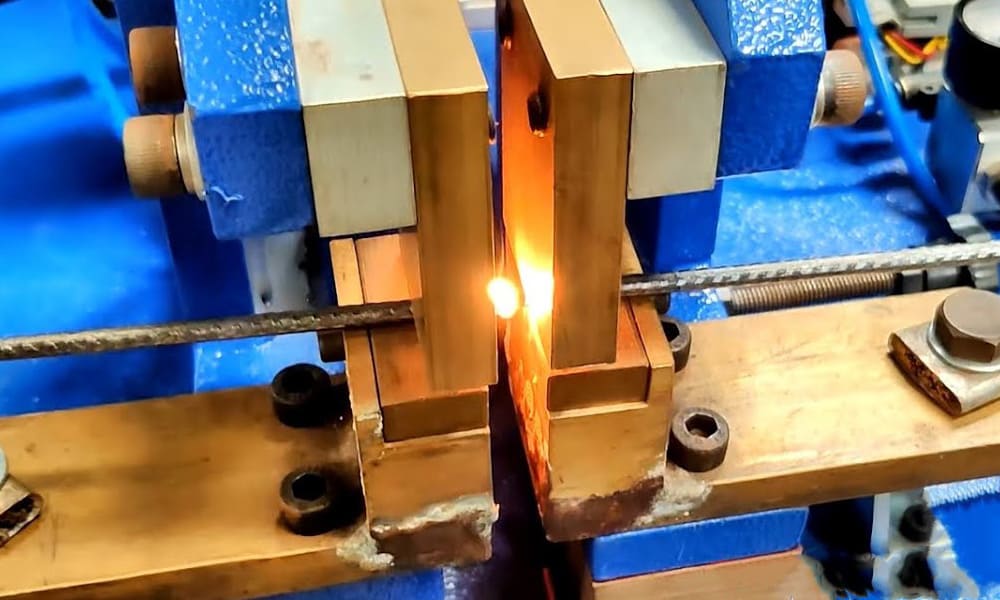

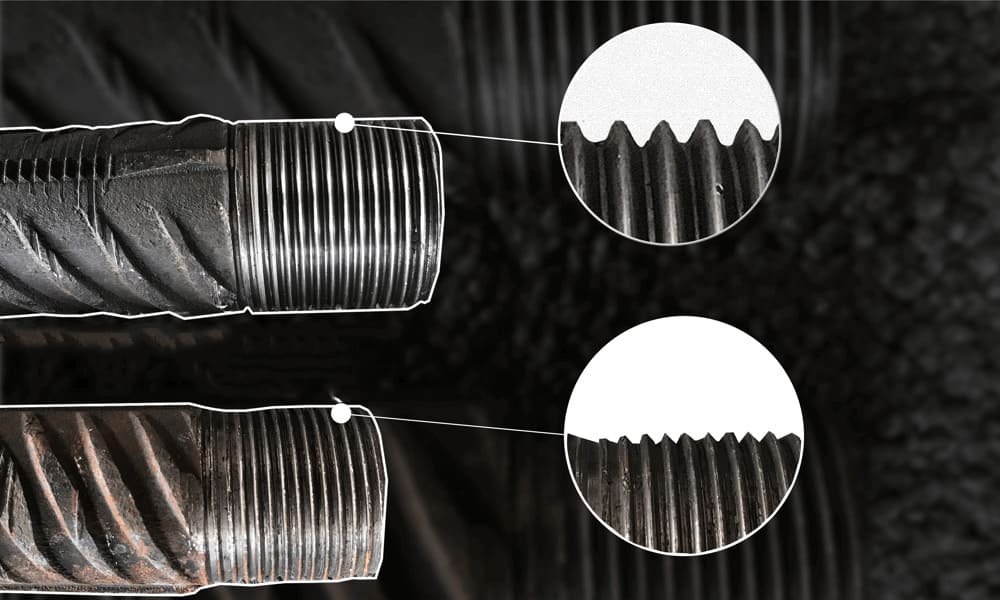

3.Threading Machine Maintenance:

-

- Inspect the threading wheel, eccentric shaft, and bearing washer on the threading machine. Replace these components if necessary and ensure all screws are tight.

4.Grinder Maintenance:

-

- Check the connecting screws of the grinder daily to ensure they are secure.

- Examine the wear on the cutter of the grinder every day and replace it if needed.

Specific Component Care

1.Saw Blade and Emulsion:

-

- Inspect the saw blade and emulsion levels on the sawing machine daily. Regularly add lubricating oil to ensure smooth operation.

2.Feeding and Discharging Alignment:

-

- Ensure that the feeding and discharging systems are kept parallel to the sawing machine inlet to avoid misalignments and inefficiencies.

3.Control System LCD Screen:

-

- Protect the LCD screen from sharp objects and impacts.

- Avoid pointing, drawing, or tapping on the screen with fingers.

- When cleaning the screen, use a soft paper towel or cotton cloth to gently wipe away dust.

Additional Tips

Inspection and Cleaning

- Conduct a thorough inspection of all machine parts at the end of each workday.

- Clean the machines regularly to prevent the buildup of dust and debris, which can affect performance and cause damage.

Lubrication and Coolant Management

- Regularly check and maintain proper levels of lubricants and coolants. This reduces friction and heat, ensuring smooth and efficient machine operation.

- Use only recommended types of lubricants and coolants to avoid damaging the machinery.

Component Replacement

- Keep track of the wear and tear of critical components and replace them as needed. This includes saw blades, threading wheels, eccentric shafts, bearing washers, and cutters.

- Maintain an inventory of spare parts to minimize downtime during maintenance.

Training and Safety

- Ensure all operators are adequately trained on the proper use and maintenance of the production line.

- Implement and follow safety protocols to protect both the operators and the machinery.

Conclusion

Regular and thorough maintenance of the CNC steel bar sawing and polishing production line is essential for its longevity and efficient operation. By following the outlined maintenance tasks and precautions, you can ensure the production line remains in optimal condition, reducing downtime and improving productivity. Proper care and timely inspections will also help in preventing major breakdowns and extending the lifespan of the equipment.