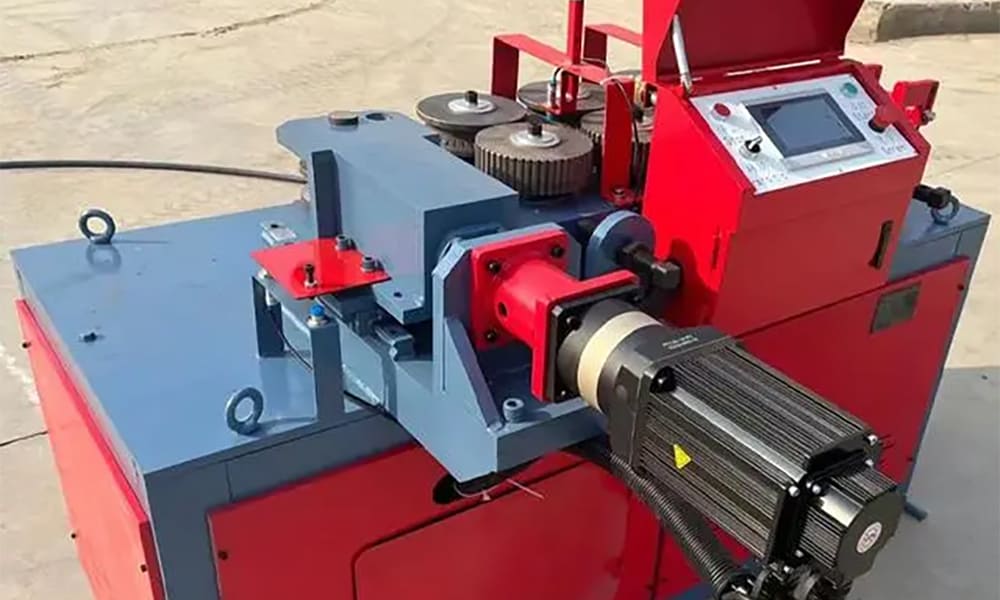

With the rapid growth of infrastructure projects, including tunnels and culverts, bending invert steel bars has become a critical aspect of tunnel construction. The tunnel invert steel bar bending machine, also known as the CNC nine-wheel arc bending machine, is a specialized piece of equipment designed to tackle this challenge efficiently. It is capable of bending various types of arc steel bars, including tunnel, culvert, wind, and water conservancy steel bars, with high precision.

Safety Precautions

To ensure safe installation and operation of the machine, it is essential to observe the following safety measures:

- Professional Installation

- Have qualified professionals install the equipment and control box.

- Electrical engineers should confirm that the power supply is turned off before any wiring to avoid the risk of electric shock.

- Power Supply Safety

- Always disconnect the peripheral power supply during maintenance and servicing to prevent accidents.

Operating Instructions

Step 1: Safety and Precautions

Familiarize yourself with all safety precautions and ensure professional installation and maintenance to mitigate risks.

Step 2: Startup and Configuration

Upon startup, set the parameters for bending arcs, including:

- Number of arcs

- Total segments (including straight lines)

- Itinerary for each section

- Length of each section

Ensure that all configurations are accurate to avoid operational errors.

Step 3: Parameter Input

Input the correct values for the following parameters:

- Reduction ratio

- Screw pitch

- Encoder lines

- Roller circumference

Confirm all parameters before proceeding with the operation.

Advanced Settings

Access the advanced settings interface to select between two working states, enhancing versatility and customization options.

Key Features

- Multi-Arc Bending

The machine can bend multiple arcs in one steel bar, providing flexibility for various applications. - Wide Diameter Range

Capable of bending steel bars with diameters ranging from 12 to 32 mm, accommodating diverse project requirements. - Precision and Efficiency

Ensures precise bending with minimal error, enhancing productivity and quality in construction projects. - User-Friendly Interface

An intuitive interface simplifies operation and configuration, improving the overall user experience. - Versatility

Suitable for a wide range of applications in tunnel construction, culvert projects, wind power generation, and water conservancy initiatives.

Conclusion

The tunnel invert steel bar arc bending machine is an essential tool for modern tunnel construction projects, providing precise and efficient bending of steel bars. With its advanced features and user-friendly interface, it significantly enhances productivity and quality while ensuring safety and reliability. As infrastructure development continues to expand, this machine plays a crucial role in meeting the evolving demands of the construction industry.

This rewrite emphasizes SEO-friendly language, enhancing readability and clarity while maintaining keyword relevance for better search engine optimization.