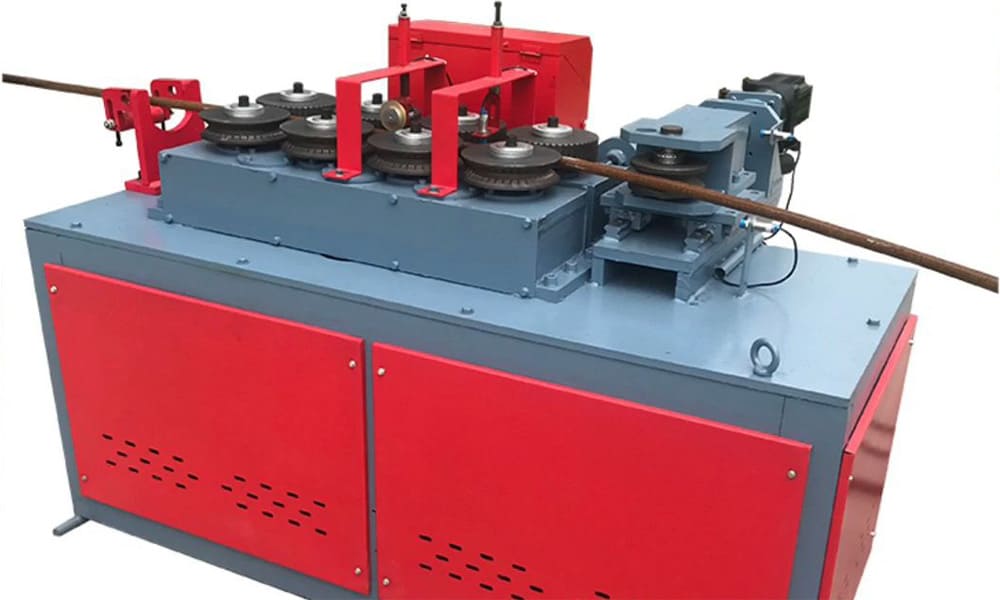

CNC steel bar nine wheel arc bending machine revolutionizes steel bar bending with its multi-section arc capabilities. This versatile machine is adept at bending tunnel flower arch steel bars, culvert arc steel bars, tunnel invert steel bars, and more, enabling precise and efficient bending of steel bars in multiple arcs.

Operational Guidelines

- Parameter Setting Interface:

-

- Enter the setting interface by touching the parameter setting button in standby mode.

- Input correct values based on the actual conditions of the device:

-

-

- Distance between encoder and voltage arc silver.

- Servo stroke (maximum working stroke of the screw).

- Sharp bending speed (transmission speed when servo motor is running).

- Slow bay speed (transmission speed after the servo motor is in place).

- Arc-free speed (speed when transmitting straight line).

- Servo forward speed (servo bending speed).

- Servo retreat speed (servo bending speed during manual testing).

- Servo jog speed.

- Servo return to origin speed.

- Set time delays as per actual requirements.

-

2. Advanced Settings Interface:

-

- Tap the advanced settings button on the parameter setting interface to access advanced settings.

- Configure settings for the number of diameter changes, diameter change angle, and arc radius.

Key Features

- Versatile Arc Bending: Capable of bending steel bars in multi-section arcs, offering flexibility for various applications.

- Precision and Efficiency: Ensures precise and efficient bending, enhancing productivity and quality of bent steel bars.

- User-Friendly Interface: Intuitive interface with parameter setting options and advanced settings for customized configurations.

- Hydraulic System: Equipped with a fully automatic hydraulic system for seamless operation and optimal performance.

- Automated Processes: Enables one-time setting for diameter changes, diameter change angle, and arc radius, streamlining operations.

Applications

- Construction Industry: Ideal for bending tunnel flower arch steel bars, culvert arc steel bars, and tunnel invert steel bars in construction projects.

- Infrastructure Projects: Suitable for various arc bending requirements in infrastructure development, including bridges, tunnels, and culverts.

- Manufacturing Sector: Used in steel fabrication facilities for producing bent steel bars with precision and efficiency.

Conclusion

The CNC steel bar nine-wheel arc bending machine is a game-changer in steel bar bending technology, offering versatility, precision, and efficiency. With its ability to bend steel bars in multiple arcs and its user-friendly interface, it enhances productivity and quality in various construction and manufacturing applications. By streamlining arc bending processes, this machine contributes to the advancement of modern construction practices and infrastructure development.