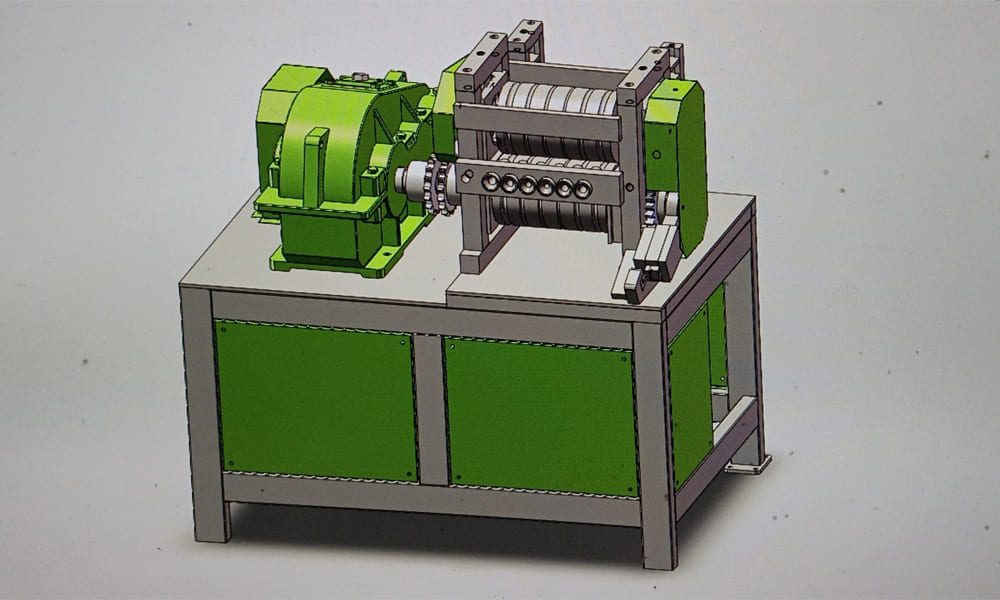

A waste steel bar straightening machine is a specialized device used for straightening and cutting scrap steel bars. It is compact, easy to move, and highly efficient. With safe operation and a long service life, it is an ideal tool for processing scrap steel bars ranging from 6mm to 25mm in diameter. The machine can straighten bent steel bars over 80cm in length in a single pass. Its high-speed rotating cylinder, driven by a belt and motor system, effectively straightens the bars while removing surface rust. This machine is particularly suitable for construction projects, such as highways, bridges, concrete components, and prefabricated board plants.

Factors to Consider When Choosing a Scrap Steel Bar Straightening Machine

Choosing the right scrap steel bar straightening machine can significantly impact your production efficiency and the quality of your final product. Here are the key factors to keep in mind:

- Steel Bar Diameter and Length Compatibility

Different machines have varying capacities. Select a machine that matches the diameter and length range of the steel bars you plan to process. - Production Efficiency

For large-scale operations, opt for a high-efficiency machine that can handle high-volume production without compromising on quality. - Quality Requirements

If precision and quality are top priorities, choose a machine designed for high-precision straightening. This ensures that the steel bars are straightened accurately with minimal deformation or surface damage.

Operation Steps for a Scrap Steel Bar Straightening Machine

Operating a scrap steel bar straightening machine is straightforward and involves the following steps:

- Insert the Scrap Steel Bar

Place the scrap steel bar into the machine’s feed port. - Power On the Machine

Turn on the machine and start the straightening process. - Adjust Machine Settings

Modify parameters such as speed and straightening strength based on the specific steel bar dimensions. This ensures that the output meets your quality standards. - Collect and Store the Finished Bars

Once the steel bars are straightened and exit through the discharge port, catch them carefully and store them according to size and type for future use.

Important Precautions When Using a Scrap Steel Bar Straightening Machine

To ensure safe and efficient operation, keep the following precautions in mind:

- Prioritize Safety Checks

Before using the machine, conduct a thorough safety check to prevent accidents. Make sure all moving parts are secure, and safety guards are in place. - Inspect Steel Bar Quality

Check the quality of the scrap steel bars before feeding them into the machine. Bars with excessive rust, bends, or damage can affect the machine’s performance. - Adjust Parameters Based on Bar Specifications

Fine-tune the machine’s settings according to the steel bar’s diameter and length. Conduct a few test runs to ensure the machine is properly calibrated before starting full-scale operations.

Conclusion

The scrap waste steel bar straightening machine is a crucial piece of equipment for construction and metal recycling projects. By selecting the right machine and following proper operation and safety guidelines, you can ensure smooth production, high-quality results, and long-term efficiency. Understanding how to choose and use this equipment effectively will help you maximize the value of your scrap steel bars while minimizing downtime and operational risks.