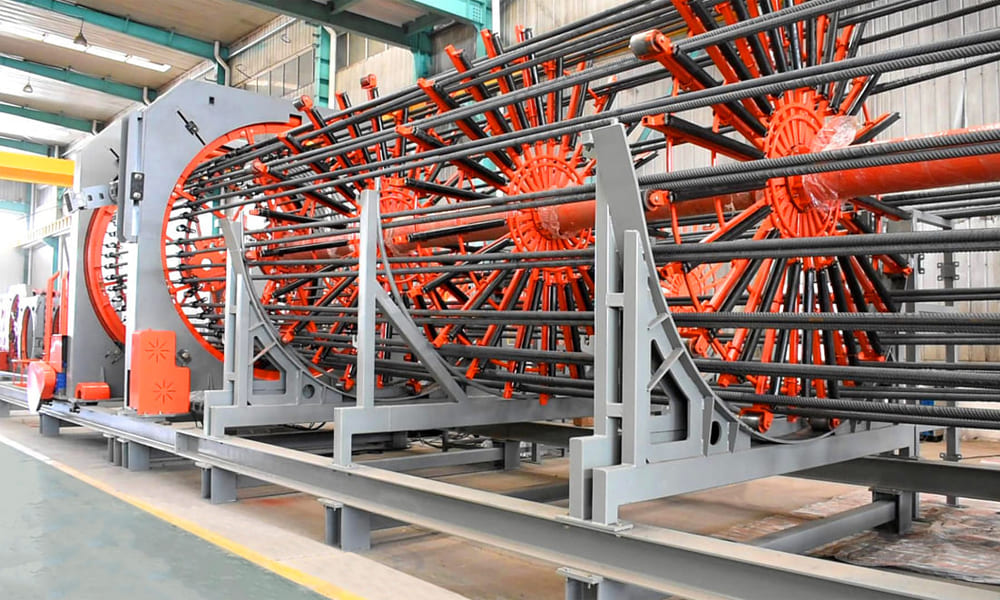

The CNC steel pile cage welding machine is a revolutionary piece of equipment controlled by PLC, designed for processing and manufacturing steel cages. Its introduction has marked the end of manual steel cage binding, significantly enhancing efficiency in the production of bridges and high-speed railways.

Working Principle

The machine’s operation revolves around the precise placement and welding of main bars and winding bars to form steel cages. This process involves fixing main bars through round holes on rotating discs, welding winding bars to main bars, and rotating the discs to wrap the rebar around the main reinforcement while welding simultaneously.

Accuracy Assurance

The CNC steel cage welding machine ensures high precision in stirrup spacing, critical for construction purposes. Parameters set on the PLC control rotation and walking speeds, guaranteeing stable spacing and impeccable accuracy throughout production.

Key Features

- Fast Processing Speed: With a team of 5 workers per shift for material preparation and welding, the machine can process over 20 12-meter-long finished cages per day, showcasing exceptional productivity.

- Stable Quality: Mechanized operations ensure consistent spacing, diameter, and overall quality of steel cages, meeting strict specification requirements. This reliability reduces the need for daily inspections by project supervisors.

- Material Savings: Eliminating the need for overlapping stirrups saves approximately 1.5% of materials compared to manual processes, leading to cost savings in construction.

- Convenience in Assembly: Evenly distributed main bars facilitate easy overlap of multiple steel cages, reducing lifting time and streamlining construction processes.

- Quality Control: Mechanized processing enhances overall quality control, ensuring consistent and reliable steel cage production.

Staffing and Cost Analysis

- Staffing includes 2 for material preparation, 1 for seam welding, and 2 for additional tasks like inner hoop installation, varying based on cage specifications.

- Cost components involve electricity fees averaging $2-3/ton and costs for welding wire, electrodes, and CO2 gas around $3-4/ton, highlighting cost-effective operations.

In conclusion, the CNC steel pile cage welding machine not only boosts production efficiency but also maintains high accuracy and quality control, making it a valuable asset in modern construction projects.