GHM Machinery CNC Steel Bar Sawing, Threading, and Grinding Production Line is an advanced, intelligent system for processing steel bars. Controlled by a PLC (Programmable Logic Controller), this equipment automates the sawing, threading, grinding, and upsetting of steel bars, making it ideal for use in high-speed railways, bridges, tunnels, and large steel bar factories. This automation enhances efficiency and reduces labor costs.

Key Features and Benefits

Automation and Efficiency:

- Fully automated, controlled via a high-definition touch screen.

- Processes steel bars with diameters from 12 to 40 mm.

- Replaces multiple workers, significantly boosting production efficiency and cutting costs.

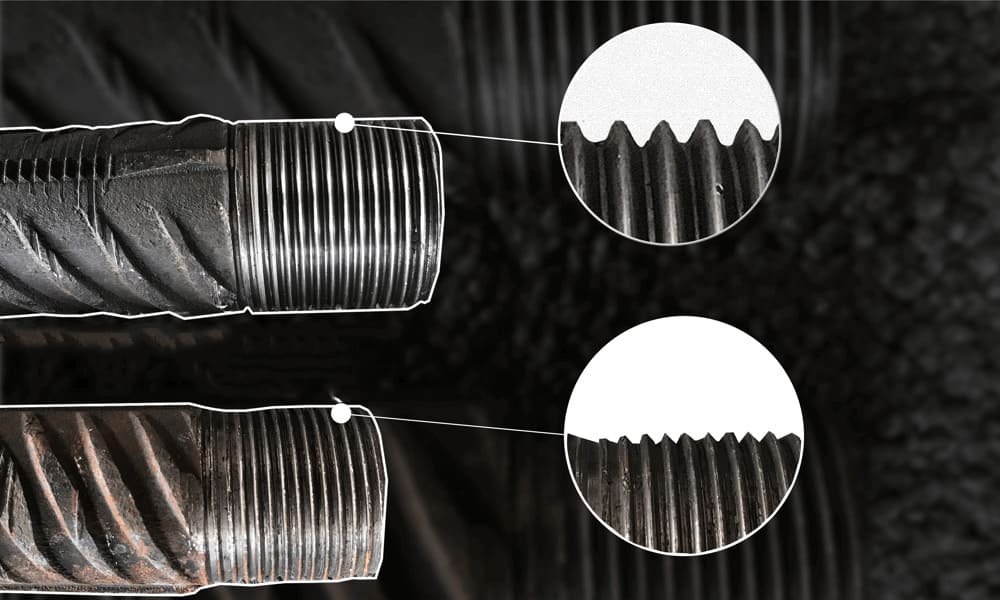

- Ensures high precision and consistent quality, perfect for large-scale construction projects.

User-Friendly Operation:

- Easy to use, requiring only one operator.

- Simple parameter setting on the main interface initiates automatic operations.

- Convenient and logical design streamlines the production process.

Comprehensive Processing:

- Automates sawing, threading, grinding, and upsetting.

- Guarantees uniformity and precision in steel bar production.

Production Process Demonstration

- Transport: Steel bars are transported to the feeding and conveying rack.

- Parameter Setting: Set parameters on the main interface and start the automatic function.

- Sawing: Steel bars are automatically sawed to the required length and sent to the discharge track.

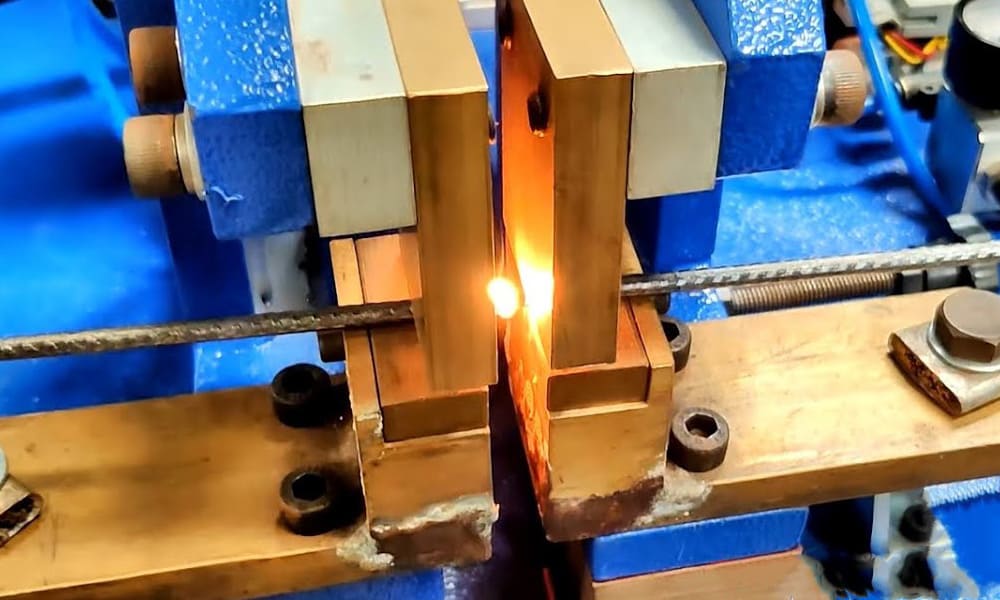

- Threading: Steel bars are flipped and conveyed to the threading station for threading.

- Grinding: Threaded steel bars are transferred to the grinding station for automatic grinding.

- Storage: Finished products are stored in the warehouse, ready for transportation.

Components

- Feeding Mechanism: Transports steel bars to the conveyor line.

- Pre-Sawing Conveyor Line: Moves steel bars to the sawing machine.

- Sawing Machine: Cuts steel bars to specified lengths.

- Post-Sawing Conveyor Line: Transports cut steel bars.

- Automatic Flipping Mechanism: Flips steel bars to the threading station.

- Threading Machines: Two machines for threading steel bars.

- Grinders: Two grinders for finishing the steel bars.

- Storage Platforms: Hold finished products.

- Electronic Control System: Manages the entire process, ensuring precision and efficiency.

Advantages for National Construction Projects

- Improved Efficiency: The automated system significantly boosts production speed and accuracy.

- Cost Savings: Reduces labor costs by requiring fewer operators.

- High Precision: Ensures processed steel bars meet project specifications.

- Enhanced Safety: Minimizes manual labor, reducing the risk of injury.

- Environmental Benefits: Intelligent design and automation lead to better energy efficiency and resource management.

The GHM Machinery CNC Steel Bar Sawing, Threading, and Grinding Production Line is a significant advancement in steel bar processing. It embodies intelligent, standardized, and efficient construction principles, making it an indispensable asset for large-scale infrastructure projects.