4-12 Steel Bar Straightening Machine Technical Requirements to be Noted

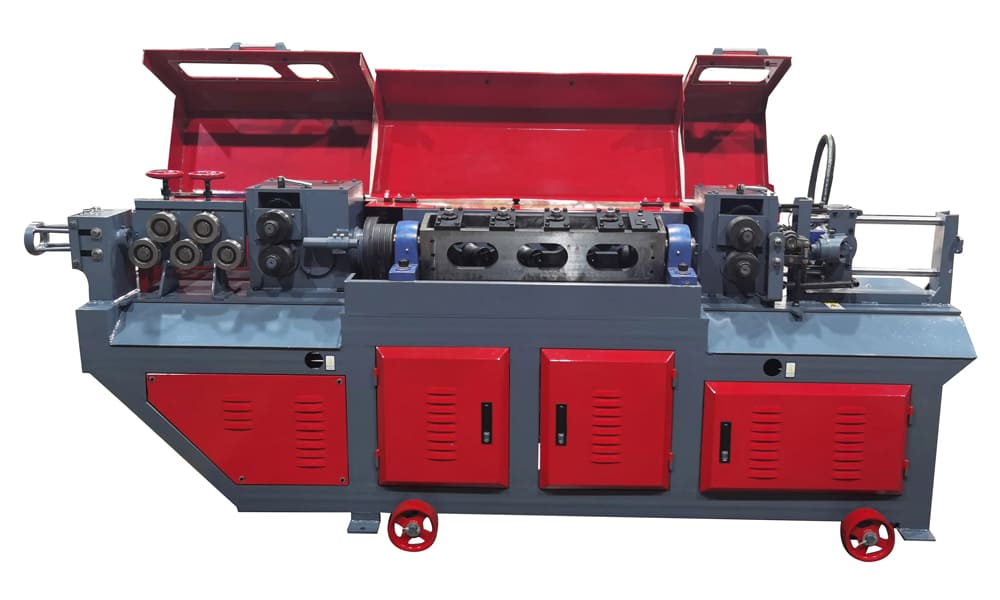

1. 4-12 Steel Bar Straightening Machine Main Machine Selection

- Functions: The main machine should offer essential functions such as adjustment, cutting, and feeding.

- Performance: Look for high precision and low noise features to ensure optimal performance and quality output.

2. Motor Selection

- Core Component: The motor is a critical part of the steel bar straightening machine.

- Features: It should be high efficiency, durable, and produce low noise with low energy consumption.

- Recommendation: Opt for a frequency converter motor that allows for speed adjustment to suit various operational needs.

3. Auxiliary Machine Selection

- Components: Auxiliary machines include feeders, cutters, and chip conveyors.

- Importance: These components are as important as the main machine for stable production.

- Compatibility: Choose auxiliary machines that are compatible with the main machine to ensure a seamless and reliable production process.

Technical Requirements to be Noted During Operation and Maintenance

1. Operating Specifications

- Qualifications: Operators must possess relevant qualification certificates.

- Procedure Compliance: Strictly adhere to operating procedures to ensure safe and stable machine use.

- Safety: Follow all guidelines meticulously to prevent accidents and ensure smooth operations.

2. Lubrication Maintenance

- Importance: Proper lubrication reduces machine wear and extends the machine’s lifespan.

- Routine Checks: Regularly inspect the lubrication status of the equipment.

- Maintenance: Perform necessary lubrication maintenance as per the manufacturer’s guidelines.

3. Air Pressure Requirements

- Pneumatic Components: The machine uses pneumatic components, requiring stable air source pressure.

- Air Source: Ensure the machine is provided with a sufficient and stable air source to maintain optimal performance.

Technical Requirements for Safety Assurance

1. Electrical Installation

- Professional Installation: Ensure installation by professional electricians.

- Regulatory Compliance: Follow relevant regulations and national electrical safety standards.

- Safety: Proper installation is crucial to avoid electrical accidents during machine use.

2. Protective Measures

- Safety Facilities: Equip the machine with protective facilities such as loading and unloading guards.

- Operator Safety: Ensure the safety of operators and surrounding personnel by using these protective measures.

3. Equipment Inspection

- Pre-Use Check: Conduct a comprehensive inspection before each use.

- Operational Assurance: Ensure all parts of the equipment are functioning normally.

- Accident Prevention: Regular inspections help prevent safety accidents and ensure efficient machine operation.

Summary:

The technical requirements for a 4-12 steel bar straightening machine cover essential aspects such as purchasing, operation, maintenance, and safety assurance. By understanding and implementing these requirements, operators can ensure the safe, efficient, and reliable use of the equipment. Following these guidelines not only enhances performance but also extends the lifespan of the machine, contributing to a smoother and more productive workflow in construction and infrastructure projects.