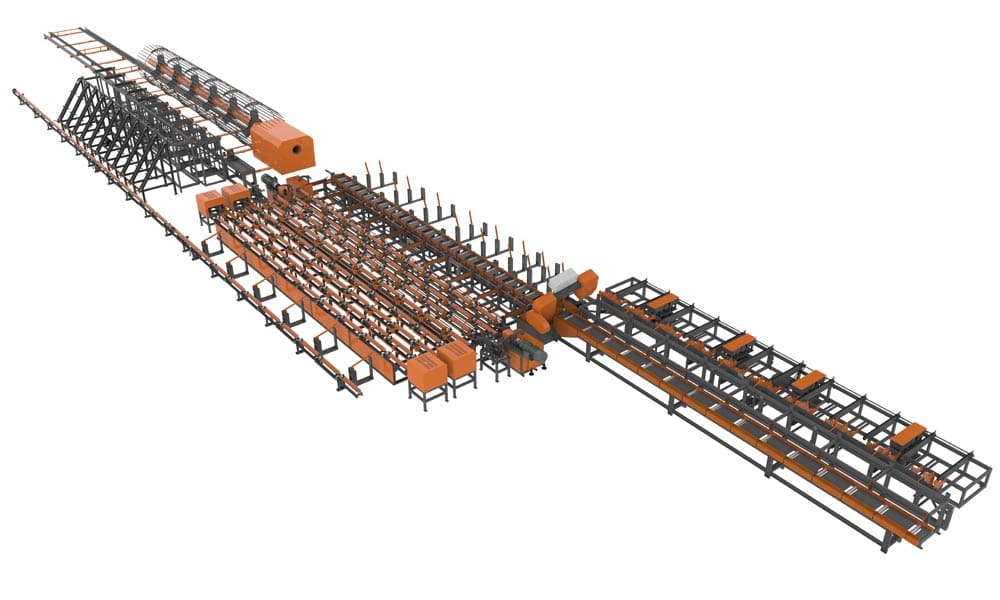

The fully automatic steel cage welding workstation is engineered to address the safety, comfort, simplicity, and convenience requirements of users in the construction industry. Designed with a deep understanding of workers’ operating habits and the necessity for quick adaptation to new equipment, this workstation offers a highly optimized user experience. Here, we delve into the features and benefits of this innovative welding workstation.

Key Features of the Welding Workstation

User-Friendly Operation:

- Intuitive Input: After initial debugging, all essential parameters for product type changes (such as steel cage diameter, winding diameter, number of main bars, and welding time) are input in a wizard-style manner. This ensures that data entry is straightforward and logical, enhancing accuracy and convenience.

- Parameter Separation: The system separates information input, parameter setting permissions, and equipment operation permissions. This isolation ensures that system parameter settings, workpiece processing specification input, and worker processing operations remain clear and simple, preventing incorrect parameter modifications.

Automated Workflow:

- Full Automation: Once product specifications are set, the equipment operates automatically, performing all welding and testing tasks without the need for constant human oversight.

- Completion Alerts: Upon completing welding tasks, the equipment automatically stops and alerts workers via broadcast messages, ensuring timely attention to completed tasks.

24/7 Operation Capability:

- Increased Efficiency: Designed to operate continuously for 24 hours, seven days a week, the workstation significantly boosts production efficiency, supporting the swift advancement of construction projects.

- Labor Reduction: During normal operations, no personnel need to remain on-site, allowing operators to focus on other preparatory tasks and reducing overall labor intensity.

High Intelligence and Safety:

- Error Minimization: The intelligent design minimizes the risk of operator errors. It takes only a few minutes for personnel to become familiar with the equipment operation, thanks to its simplified and intuitive interface.

- Quality and Efficiency: By enhancing the product’s intelligence, the workstation ensures consistent construction quality, improves operational efficiency, and reduces costs. This results in significant benefits for cooperative enterprises, including better quality assurance and lower skill requirements for personnel.

Benefits for Construction Projects

Enhanced Safety and Comfort:

The workstation prioritizes user safety and comfort, reducing the risk of accidents and ensuring a better working environment for operators.

Operational Simplicity:

- With a user-friendly interface and simplified operation steps, the workstation ensures that even new users can quickly adapt to the equipment, reducing training time and increasing productivity.

Improved Production Efficiency:

Continuous 24/7 operation and automated welding tasks drastically improve production efficiency, supporting faster project completion times.

Labor Intensity Reduction:

By automating welding and testing processes, the workstation reduces the physical strain on workers, allowing them to engage in other essential tasks and improving overall workflow.

Cost Reduction:

The reduction in labor intensity, combined with improved operational efficiency, leads to significant cost savings for construction projects.

Conclusion

The fully automatic steel cage welding workstation represents a significant advancement in construction technology. By prioritizing user needs and integrating intelligent design features, it ensures safe, comfortable, and highly efficient operations. This innovative equipment not only enhances production efficiency but also reduces labor intensity and operational costs, making it an invaluable asset for modern construction projects.