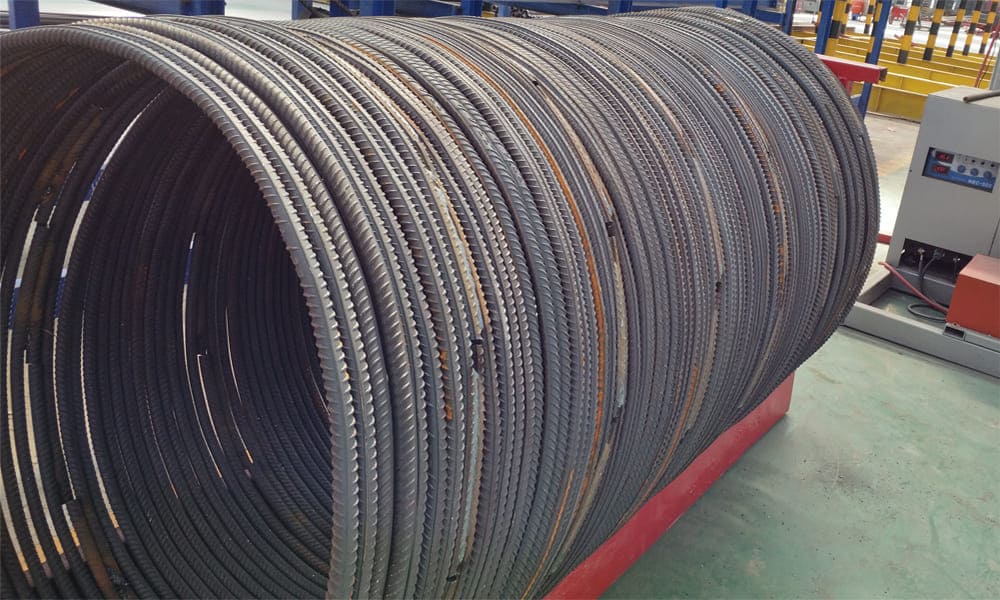

CNC Steel Rod Ring Making Machine, also known as an automatic steel bar welding and ring bending machine, is a cutting-edge innovation in steel bar processing technology. This fully automated machine simplifies complex tasks such as bending, welding, and cutting steel bars into circular shapes, offering numerous benefits for a wide range of construction projects.

CNC Steel Rod Ring Making Machine Key Features and Advantages

- Seamless Automation

The CNC steel bar ring making machine operates without manual intervention, automating the complete process of bending, welding, and cutting steel bars into circular forms. This not only improves efficiency but also significantly boosts productivity. - Versatile Applications

It is widely used for bending circular stirrups and reinforcing bars within steel cages for diverse construction projects, including bridges, residential developments, pipe corridors, and foundation steel bars for large-scale projects. - Broad Processing Capability

This machine can handle steel bars with diameters ranging from 12 to 32 millimeters. It also fabricates rings with diameters from 0.5 meters to over 2 meters, making it suitable for a variety of construction requirements. - Smooth and Efficient Workflow

Steel bars are automatically fed into the bending apparatus, where they undergo precision bending into circular shapes. They are then transferred to the secondary welding unit for automatic welding, followed by a specialized cutting machine for final shaping—ensuring a smooth, uninterrupted production process. - Enhanced Efficiency and Labor Savings

By eliminating manual labor, the CNC steel bar ring making machine reduces labor costs and shortens project timelines, making it a cost-effective solution for construction companies. - Improved Safety and Environmental Benefits

Automation minimizes the risks associated with manual handling, promoting a safer work environment. Additionally, it reduces resource consumption and minimizes material waste, contributing to environmental sustainability. - Superior Quality Assurance

With precise control over bending, welding, and cutting, the machine ensures consistent and high-quality finished products. Each unit undergoes rigorous quality control, guaranteeing superior results in every project. - Cost-Effectiveness

In light of rising labor costs, adopting CNC steel bar processing technology proves to be a smart investment. It optimizes project expenses while enhancing overall quality and competitiveness in the market.

Future Outlook

As the construction industry evolves with rapid advancements in technology, there is a growing shift towards intelligent manufacturing. The demand for advanced steel bar processing and distribution technology is increasing, driven by the need for efficiency, quality, and safety. The CNC steel bar ring making machine stands out as a pioneering solution that meets these demands, redefining the future of construction not only in China but also worldwide.

Conclusion

In summary, the CNC Steel Bar Ring Making Machine is a groundbreaking innovation in steel bar processing, offering fully automated operations, versatile applications, significant labor savings, and a strong focus on quality assurance. As the construction industry embraces more intelligent solutions, the widespread adoption of such advanced equipment is set to transform construction practices on a global scale.