The CNC steel bar ring making machine, also recognized as an automatic steel bar welding and ring bending machine, stands at the forefront of steel bar processing technology, marking a significant leap forward in the construction industry. This fully automated apparatus simplifies the intricate tasks of bending, welding, and cutting steel bars into circular forms, presenting a multitude of advantages and versatile applications across diverse construction projects.

Key Features and Functions:

- Seamless Automation: Operating without the need for manual intervention, the CNC steel bar ring making machine automates the entire process of bending, welding, and cutting steel bars into circular shapes, optimizing efficiency and productivity.

- Versatility in Application: Primarily employed for bending circular stirrups and reinforcing bars within steel cages for a range of construction endeavors, including bridges, residential developments, pipe corridors, and foundation steel bars for large-scale projects.

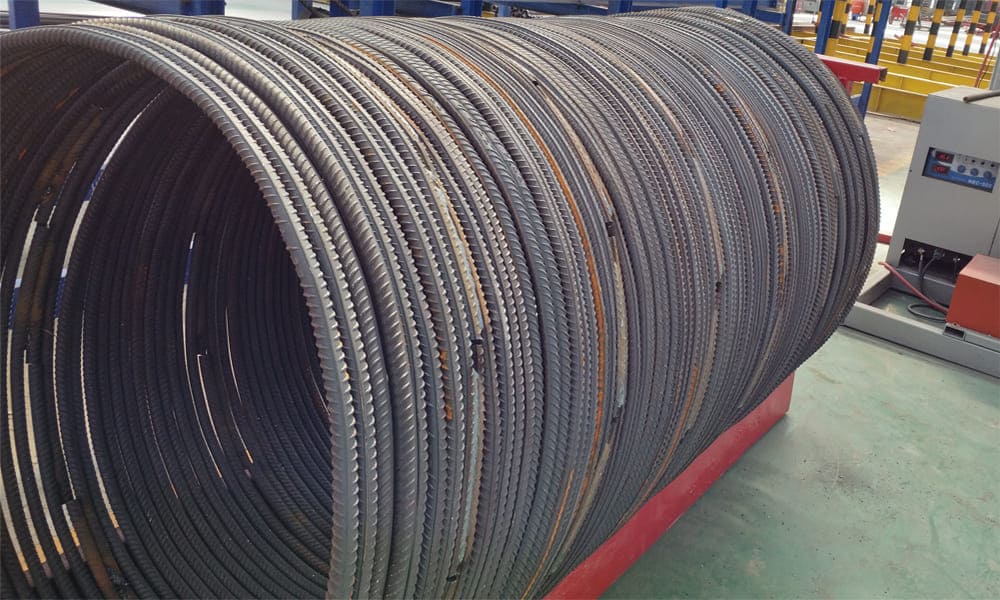

- Broad Processing Capability: With the ability to handle steel bars ranging from 12 to 32 millimeters in diameter, this machine can fabricate circles with diameters spanning from 0.5 meters to 2 meters or beyond, catering to diverse project requirements.

- Sequential Workflow: Steel bars are seamlessly transferred to the bending apparatus, where they undergo precision bending into circular shapes. Following bending, the bars are automatically welded by a secondary welding unit and subsequently cut by a specialized cutting machine, ensuring a smooth and uninterrupted workflow.

- Efficiency and Labor Savings: By eliminating manual labor, the CNC steel bar ring making machine not only reduces labor costs but also enhances operational efficiency, consequently minimizing construction timelines.

- Safety and Environmental Consciousness: Automation mitigates the risks associated with manual labor, promoting a safer work environment. Additionally, it contributes to environmental sustainability by reducing resource consumption and minimizing waste.

- Quality Assurance: With meticulous attention to detail, the machine ensures precise bending, welding, and cutting of steel bars, resulting in superior-quality finished products upheld by stringent quality control protocols.

- Cost-Effectiveness: Against the backdrop of escalating labor costs, the integration of CNC steel bar processing technology proves cost-effective, optimizing construction expenditure while elevating overall quality and competitiveness.

Future Outlook:

Amidst the rapid advancements in science and technology, the construction industry is undergoing a paradigm shift towards intelligent manufacturing. As the demand for cutting-edge steel bar processing and distribution technology burgeons, propelled by imperatives of efficiency, quality, and safety, the CNC steel bar ring making machine emerges as a pioneering solution poised to address the evolving needs of the construction landscape.

In summary, the CNC steel bar ring making machine represents a seminal advancement in steel bar processing, characterized by its fully automated operation, diverse applications, labor-saving attributes, and unwavering commitment to quality assurance. As construction technology progresses, the widespread adoption of such advanced equipment is poised to reshape the contours of the construction industry, not only in China but also on a global scale.