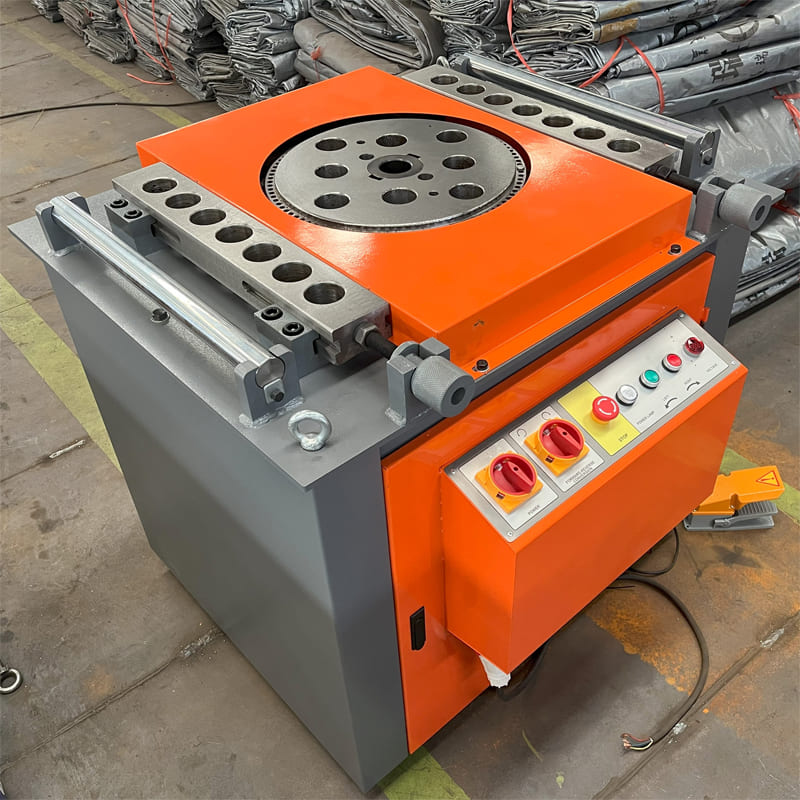

| GW52D Rebar Bending Machine | ||

| Bending Capacity | II Rebar(≤450N) | ≤ø50mm |

| III Rebar(≤650N) | ≤ø40mm | |

| Working Dish Size | ø400mm | |

| Spindle Speed | 7- 10rpm | |

| Motor Power | 4kw(3 Phase) | |

| Weight | 484kg | |

| Dimension | 1050*910*1010 | |

| Voltage | 380v/220v/415v/440v | |

GW52D Rebar Bending Machine Robust Construction:

- Fully enclosed gearbox separated from the work plate, preventing deformation and oil leakage even under heavy loads.

- Precision mold casting with thickened box walls for increased strength.

High-Quality Materials:

- Gears, gear shafts, working discs, stop gauges, saddles, pile heads, and bushings made from high-quality alloy steel with appropriate heat treatment (quenching/tempering/high frequency).

- Square steel and working disc made from forged carbon steel, and all pile heads and covers made from alloy steel.

Enhanced Durability:

- Long service life with parts designed to operate safely under high load conditions.

- High hardness heat treatment ensures reliable long-term use.

Accurate and Reliable Performance:

- Dust-proof brake motor and two limit switches ensure bending angle accuracy after stopping and restarting.

- Insert pinned disks and movable saddles for precise adjustment of bending angles.

Convenient and Adjustable:

- Braking motor, adjustable square steel, and latch-type positioning disc allow for convenient angle adjustment and accurate bending angles.

- The disc can automatically return to its position for easy operation.

Versatile Operation:

- Manual/automatic conversion for flexible bending methods, catering to different operational needs.