GHM Machinery Steel Bar Threading Machine is a reliable tool designed for efficient steel bar processing. To ensure safety and optimal performance, follow these guidelines:

- Designate a Trained Operator: Only certified personnel should operate the machine, ensuring proper handling and maintenance.

- Pre-Operation Inspection: Before starting, check if all components are properly installed and securely connected. Ensure all parts are well-lubricated and free from leaks. Conduct an empty run test to verify everything is functioning correctly before use.

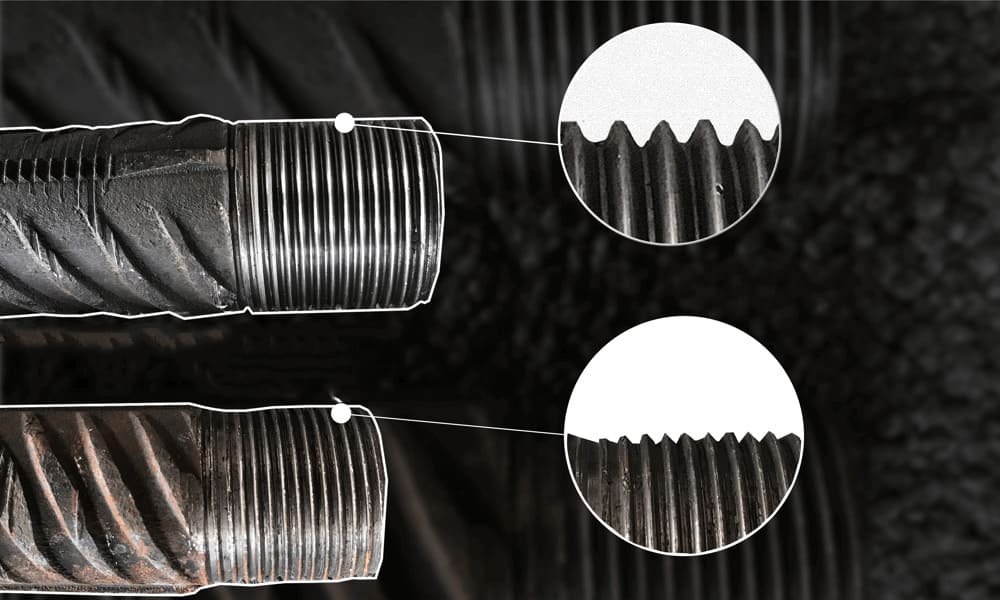

- Use Properly Cut Steel Bars: Always use steel bars cut with toothless saws to avoid blade damage and threading errors. Do not use steel bars cut by standard cutting machines, as they may lead to substandard threading quality.

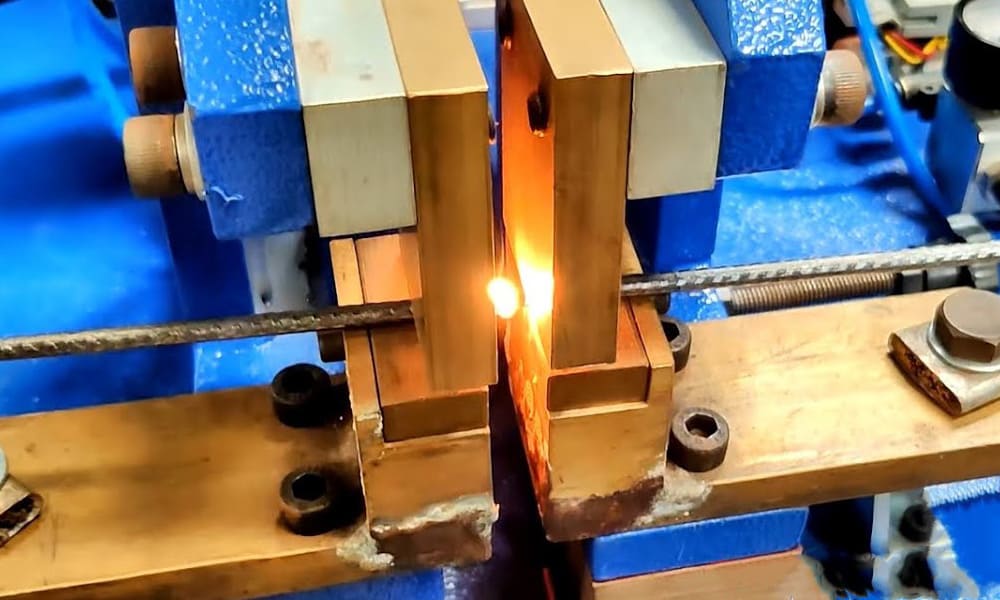

- Secure Steel Bars Firmly: When threading, make sure the steel bar is clamped securely to prevent slippage and ensure precise threading.

- Maintain Coolant Flow: Ensure continuous coolant flow during threading. Replace the coolant regularly. In winter, insulate the system and discharge water after use to prevent damage to the water pump and motor.

- Avoid Cleaning During Operation: Never clean the blades or remove debris while the machine is running. If operational issues arise, stop the machine immediately for inspection and repair.

- Adhere to Performance Limits: Do not exceed the machine’s specified performance parameters to prevent accidents and equipment damage.

- Follow Proper Maintenance Practices: Implement regular cross-check inspections to maintain the machine in good working condition.

- Do Not Perform Maintenance While Running: Always turn off the machine before performing any maintenance tasks.

- Power Down After Use: After completing work, turn off the power and securely lock the control box.

By adhering to these safety guidelines, you can ensure the safe and efficient operation of your GHM Machinery Steel Bar Threading Machine.