Skip to content

Steel Bar Threading Machine Pre-Operation Checks

- Steel Bar Threading Machine Electrical Inspection:

- Inspect electrical parts for any damage.

- Ensure the machine body is properly grounded.

- Power Supply Verification:

- Confirm that the power supply voltage matches the machine’s working voltage.

- Ensure the distribution box is located within 3 meters of the motor.

- Safety Components:

- Verify that the machine is installed smoothly with complete and reliable safety protection components.

Initial Setup

- Idle Test:

- Run the machine without load to test both the forward and reverse functions of the motor.

- Ensure that the machine and the water pump are functioning correctly.

Preparing Steel Bars

- Selection:

- Choose steel bars that exhibit good longitudinal linearity.

- Ensure the cut end face is perpendicular to the steel bar’s axis. If not, cut and polish the end face before threading.

Loading Steel Bars

- Teamwork for Lifting:

- With the assistance of another person, lift the steel bar onto the workbench.

- Clamp it securely and adjust for concentricity to prevent loosening and potential injuries.

Threading Process

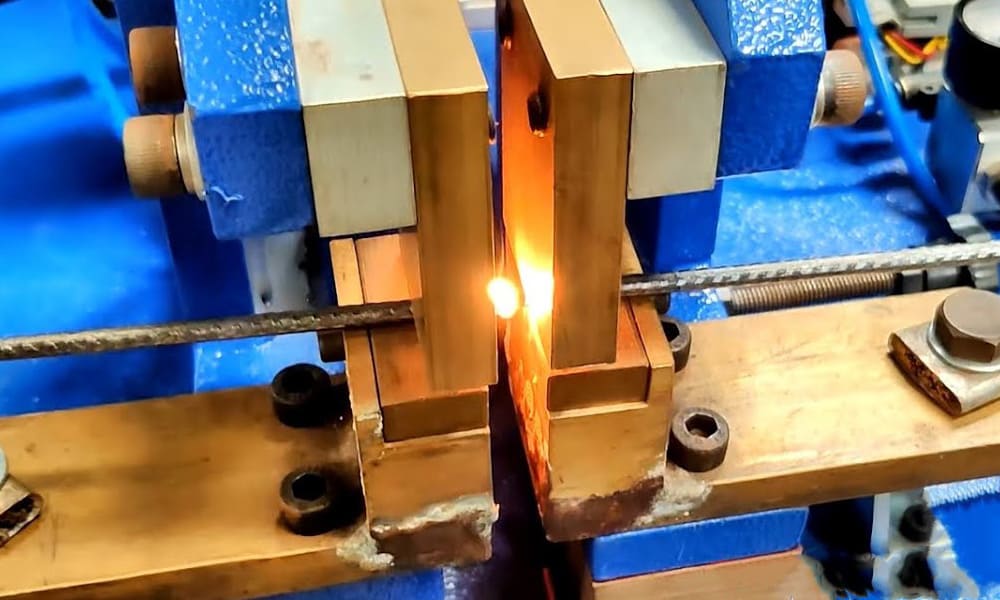

- Starting the Threading:

- Begin threading slowly, gradually increasing speed while maintaining a uniform threading speed.

- Ensure that the thread teeth remain intact to prevent equipment damage.

Handling Semi-Finished Products

- Lifting:

- After processing the first thread, use the help of another person to lift it onto the semi-finished material rack.

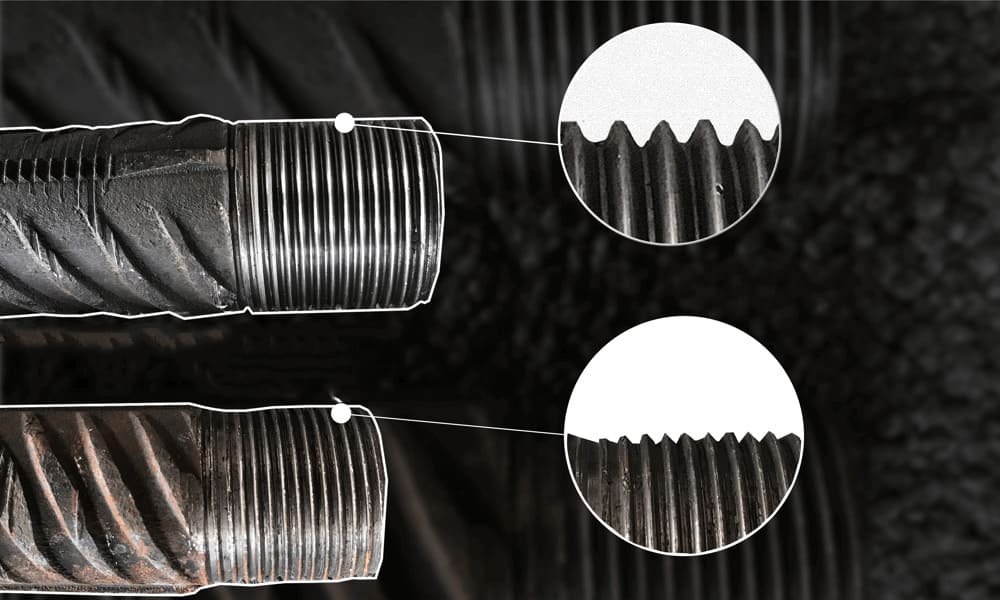

- Connect and lock it using the appropriate sleeve, ensuring proper locking and threading quality by observing and feeling for tightness.

Quality Inspection

- Sampling:

- Sample threaded connectors under the supervision of a witness and send them to the laboratory for quality inspection.

- If the laboratory inspection passes, continue processing threaded joints of the same specification.

Troubleshooting

- Immediate Actions:

- If the machine operates poorly or the knife gets stuck, stop the machine immediately for inspection and repair.

- Debris Cleaning: Do not clean debris from the blade while the machine is operating.

Safety Measures

- Personal Protective Equipment:

- Operators must wear goggles.

- Avoid touching rotating parts while wearing gloves.

Post-Processing Care

- Cleaning and Protection:

- Clean the processed threaded interface and protect it from rain and corrosion.

- Ensure the coolant is clean and free of impurities; replace it monthly.

- Add and replace gear oil in the reducer every three months.

Maintenance

- Regulatory Compliance:

- Perform maintenance and repair on the machine according to established regulations.

End of Operation

- Power Down Procedures:

- Turn off the power and lock the distribution box.

- Clean the work area before leaving.

Rebar Threading Machine

Steel Bar Threading Machine Standard Sleeve Geometric Dimension

| Specifications |

Sleeve Length (mm) |

Thread Length (mm) |

Thread Number |

Pitch (mm) |

| 16 |

45 |

22.5 |

9 |

2.5 |

| 18 |

55 |

27.5 |

11 |

2.5 |

| 20 |

60 |

30 |

12 |

2.5 |

| 22 |

65 |

32.5 |

13 |

2.5 |

| 25 |

70 |

35 |

12 |

3.0 |

| 28 |

80 |

40 |

13 |

3.0 |

| 32 |

90 |

45 |

15 |

3.0 |

Minimum Tightening Torque for Straight Thread Joint Installation

| Rebar Diameter (mm) |

Tightening Torque (N·mm) |

| ≤16 |

100 |

| 18–20 |

200 |

| 22–25 |

260 |

| 28–32 |

320 |

| 36–40 |

360 |

| 50 |

460 |