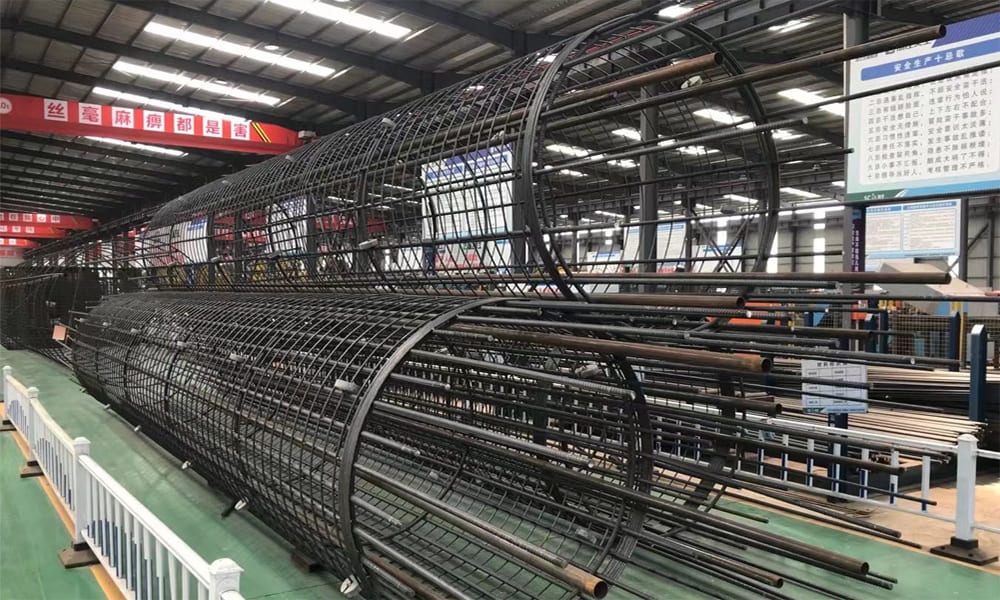

Steel Bar Cage Winding Machine mainly includes main bar rotating base, rotating drum, rotating motor unit, stirrup feeding truck and other components.

Reinforcement cage rolling machine and steel cage rolling machine are automated steel processing equipment that specializes in making steel cages.

Let me explain the operating procedures of the Steel Bar Cage Winding Machine and the use of buttons.

- Connect the main power supply to the equipment power distribution cabinet, carefully check that the connected lines are correct, and then power on and test the machine.

- First click the green start button, and then click the forward rotation button of the cart. At this time, the cart’s forward rotation flashes on the display. Note that the forward rotation of the cart means that the drum rotates toward the direction of the trolley track, which is forward rotation; otherwise, it is reverse rotation.

- Click the red stop button to stop the roller.

- Click the green start button, and then click the car forward button to start the car.Note that the forward direction of the car is from the power head to the tail. If it is forward, it is reverse.

- Click the red stop button to stop the car.

- Click the green start button, and then click the straightening and forward button to start the straightening mechanism. Watch the straightening motor fan blades clockwise for forward rotation and counterclockwise for reverse rotation.

- Click the straighten, forward or stop button again to stop the currently operating equipment. 8. Click the green start button, and then click the one-button start button. At this time, the cart motor, straightening motor, and trolley motor will start and run at the same time. Test whether the rotation direction of each motor is correct. 9. If there is an error in the direction of rotation in the future, adjust the phase sequence of the motor, and then adjust the parameters according to the instructions to wind the rib spacing that meets the requirements.

The above is the operation process description of GHM Machinery steel cage winding machine equipment, and an introduction to the use of buttons.

Here’s a step-by-step tutorial on how to use the steel cage winding machine, along with explanations of button functions:

Power Connection and Testing:

Connect the main power supply to the equipment’s power distribution cabinet, ensuring correct line connections.

Power on the machine and conduct a test to ensure proper functionality.

Starting the Roller:

Press the green start button to initiate the machine.

Click the forward rotation button of the cart. The forward rotation indication will flash on the display.

Note: Forward rotation of the cart indicates the drum rotates towards the trolley track; otherwise, it’s reverse.

Stopping the Roller:

Press the red stop button to halt the roller’s rotation.

Starting the Cart:

Press the green start button again and then click the forward button of the cart to commence its movement.

Note: Forward direction of the cart is from the power head to the tail. Reverse is the opposite.

Stopping the Cart:

Use the red stop button to stop the cart’s movement.

Initiating Straightening Mechanism:

Press the green start button once more and then click the straightening and forward button to activate the straightening mechanism.

Observe the straightening motor fan blades: clockwise for forward rotation, counterclockwise for reverse.

Halting Operation:

Press the straighten, forward, or stop button to cease the operation of the currently active equipment.

One-Button Start:

Press the green start button, followed by the one-button start button.

This initiates simultaneous operation of the cart motor, straightening motor, and trolley motor. Ensure each motor’s rotation direction is correct.

Error Correction and Parameter Adjustment:

If there’s a rotation direction error in the future, adjust the motor’s phase sequence.

Follow instructions to wind the rib spacing according to requirements.

This tutorial provides a comprehensive overview of the operation process of the GHM Machinery steel cage winding machine, including button functions for easy navigation and control.