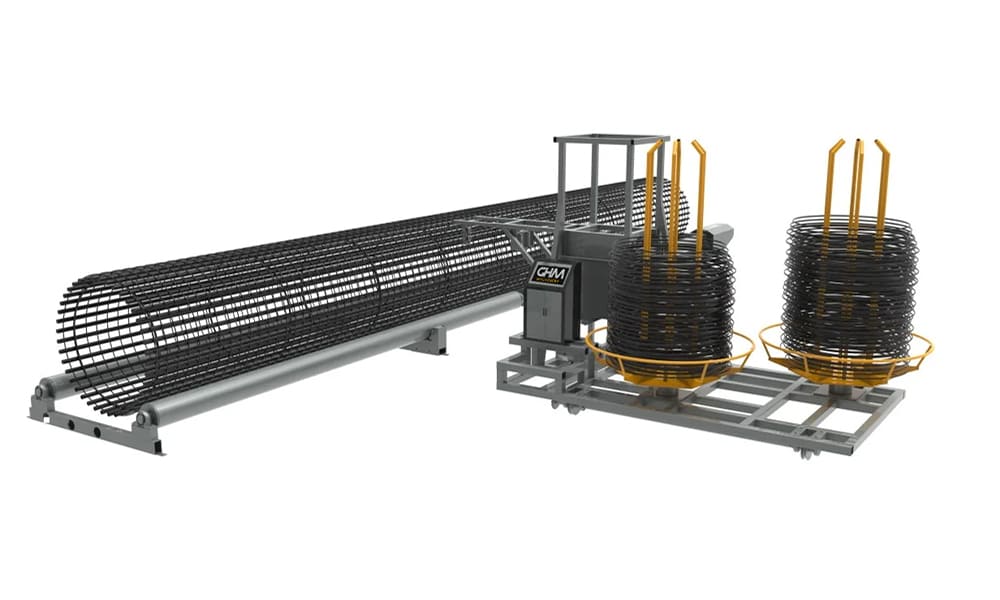

Steel bar cage winding machine is a specialized CNC device designed to wind external bars onto steel cage structures, addressing the limitations of traditional fabrication methods. By automating critical steps, it enhances efficiency, precision, and overall productivity.

Preparation and Setup

The process starts with manually welding the main bars and internal reinforcing rings to create the basic skeleton of the steel cage. Once this prefabricated frame is ready, it is placed between the two rollers of the steel cage winding machine, positioning it for subsequent winding operations.

Adjustment and Configuration

Before the machine begins winding, it’s essential to set the distance between the two rollers according to project specifications. Proper alignment is crucial to ensure the coiled bars wrap evenly around the steel cage frame, providing consistent reinforcement throughout.

Winding Process

During operation, coiled bars—also referred to as winding reinforcements—are fed through a straightening mechanism and guided into the steel cage structure. The initial ends of these reinforcements are welded to the main reinforcement of the cage, securing them in place and forming a stable starting point for the winding process.

Winding and Welding

As the machine winds the coiled reinforcement around the steel cage, it is fed through a series of fixed and moving rotating disks. This setup ensures controlled winding along the main reinforcement. Concurrently, welding operations are carried out to bond the winding reinforcement firmly to the main reinforcement, creating a strong, cohesive structure.

Final Product

Once the winding and welding processes are complete, the steel cage winding machine produces a robust, reinforced steel cage assembly. These assemblies are ideal for various construction applications, particularly in bored pile projects, where strong, durable reinforcement is essential.

Conclusion

In summary, Steel bar cage winding machine revolutionizes the fabrication of steel cages by automating the winding of external bars onto prefabricated frames. This innovative approach optimizes efficiency, flexibility, and precision, making it a cost-effective solution for modern construction projects. By significantly improving productivity and quality, it plays a vital role in ensuring successful outcomes in infrastructure and building projects.