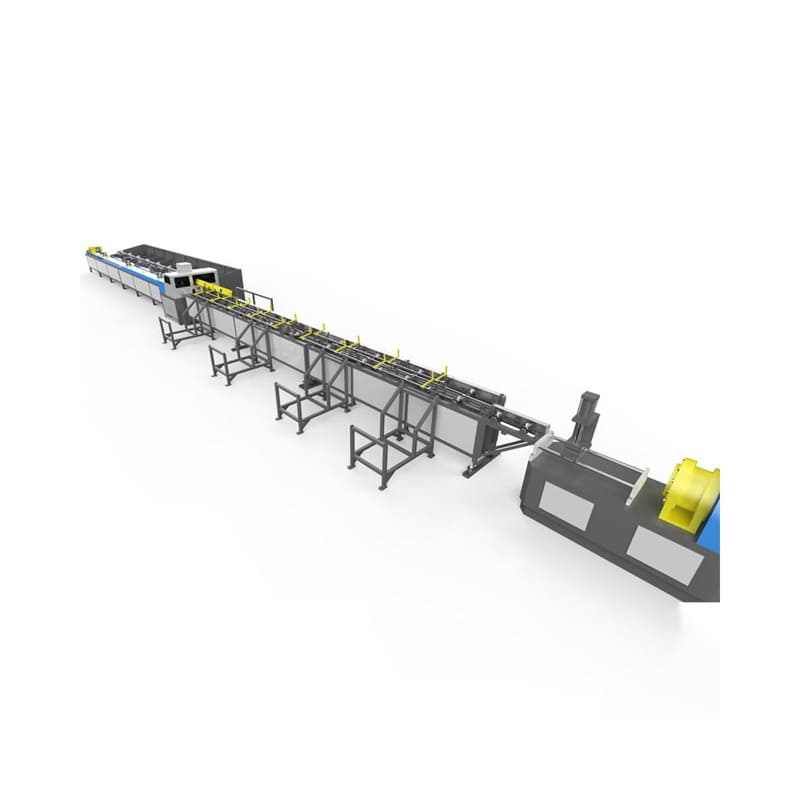

Tube Tapering Machine Line is an advanced, efficient solution for steel pipe processing. This user-friendly system integrates drilling and tapering functions into one machine, making it simple to handle everything from raw steel pipes to finished products.

| Type |

GZS108 |

| Length error |

±2mm |

| Pipe size(mm) |

∅38-∅114 |

| Length(m) |

3-15(customized) |

| Air pressure (Mpa) |

0.4-0.6 |

| Drill speed(hole/hour) |

1200-2400 |

| Pipe move speed(mm/s) |

10-565 |

| Work voltage(V) |

380 |

| Total power(kw) |

115 |

| Consumption(kw/h) |

20 |

| Weight(kg) |

12000 |

| Dimension(m) |

33*4.5*1.8 |

Tube Tapering Machine Line Key Benefits:

- Smart Control: Easily input processing settings like product length and hole spacing using the touch screen. The machine automatically adjusts for precise results.

- High Efficiency: Designed for high production rates with minimal labor, allowing one operator to manage the entire process.

- Versatile: Handles various steel pipe sizes and hole patterns, adapting to different needs.

- Easy Operation: Simple PLC control and touch screen interface make it easy to use and train new operators.

- Low Maintenance: Features built-in status detection and alerts for quick troubleshooting and reduced maintenance costs.

- Compact Design: Space-saving and easy to transport, fitting conveniently into any workspace.

Production Process:

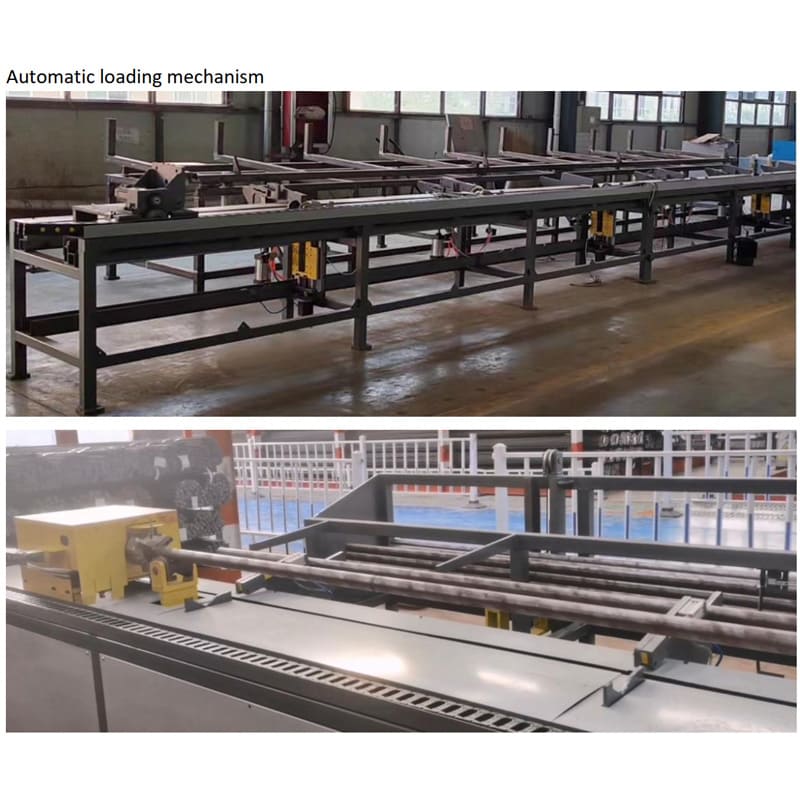

- Automatic Loading: The lifting mechanism loads and positions raw materials automatically.

- Feeding: The jacking cylinder feeds individual pipes into the machine for processing.

- Positioning and Sawing: The machine accurately cuts pipes to the desired length, with minimal waste.

- Drilling: Pipes are drilled at precise locations based on input settings.

- Sharpening: After drilling, pipes are sharpened using high-frequency heating.

- Final Processing: Completed pipes are moved to the finished product area.

This production line streamlines steel pipe processing, improving efficiency and precision while being easy to operate and maintain.