Single Rebar Threading Equipment Machine Line represents the pinnacle of innovation, seamlessly integrating international technology with electrical, hydraulic, and pneumatic systems. This machine line provides a comprehensive solution for sawing and threading steel bars, accommodating diameters ranging from 12 to 40mm and supporting rebar strengths including HRB335, HRB400, and HRB500.

Unmatched Features and Capabilities:

- Precision Control with PLC Technology

- The feeding roller is meticulously managed by a Programmable Logic Controller (PLC), ensuring exceptional precision during operations.

- Equipped with fixed baffles and a movable roller, it guarantees high accuracy and consistent performance.

- Efficient Cutting Mechanism

- The rebar cutting mechanism utilizes a metal band saw machine known for its efficiency. It optimizes cutting processes, minimizes energy consumption, and reduces material waste, all while providing a user-friendly experience.

- Innovative Raw Material Storage Rack

- The raw material storage rack is engineered for large-tonnage capacity. When paired with the automatic bar feeding machine, it facilitates seamless batching and reduces feeding cycle times, thereby enhancing overall productivity.

- Enhanced Material Handling

- The fully automated feeding roller eliminates the need for secondary raw material transportation. By automating the processes of material transportation, flipping, and transfer, it significantly boosts operational efficiency.

- Durable Steel Bar Conveying Roller

- Designed with wear-resistant V-shaped rollers, the steel bar conveying roller offers durability and quiet operation. Its robust construction ensures an extended service life with reliable performance.

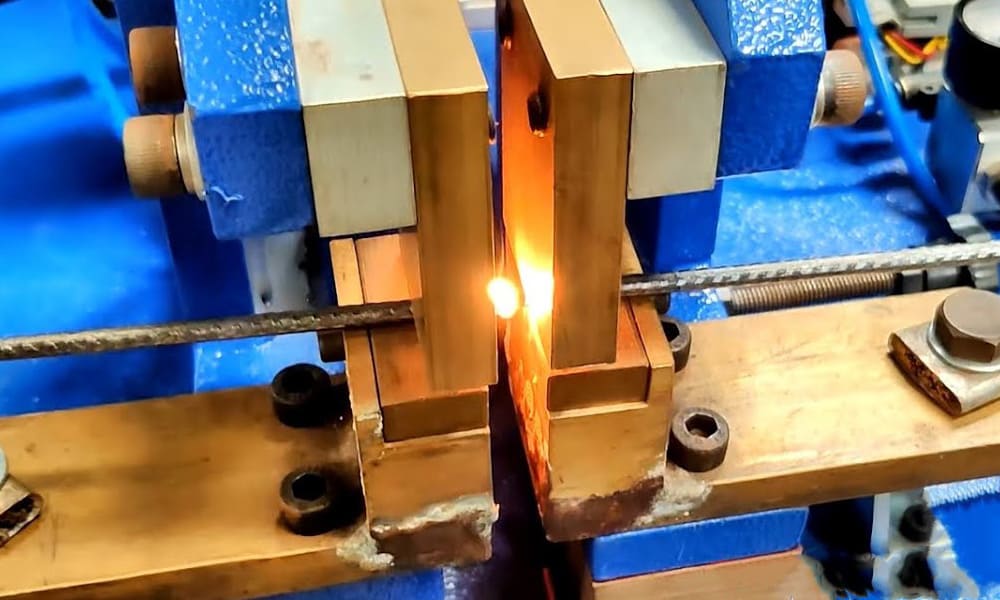

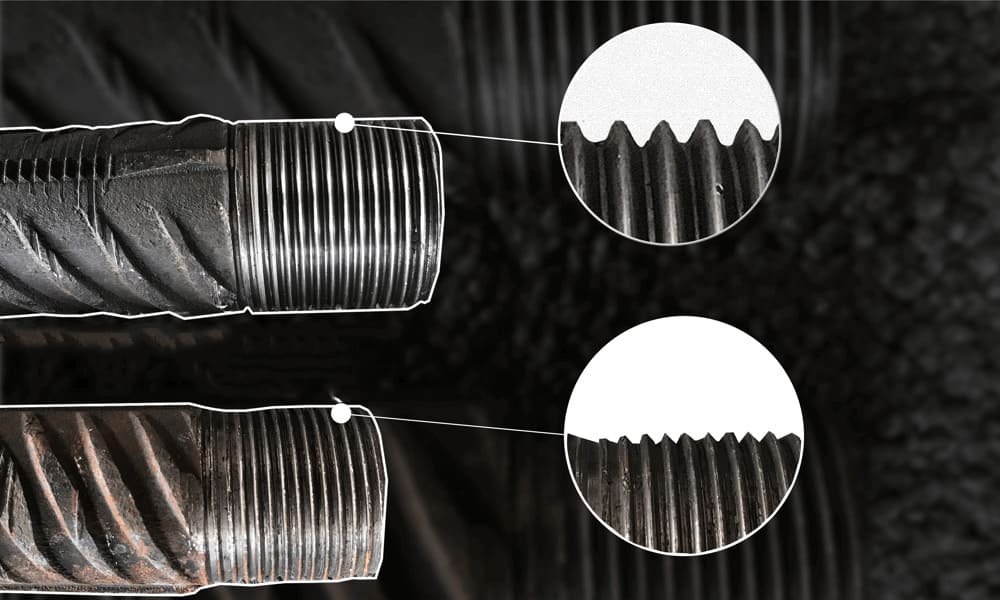

- Improved Rib Stripping and Thread Rolling

- The main head for rib stripping and thread rolling features innovative cylinder clamping and feeding functions, dramatically increasing the efficiency of the rib stripping and threading processes.

Revolutionizing the CNC Steel Bar Production Line:

Our CNC steel bar wire covering production line sets new standards for productivity and operational efficiency. Key features include:

- Automatic Conveying Platform: Utilizes 160MM seamless pipes to streamline the conveying process.

- Increased Conveying Force: The inclusion of thicker and enlarged wheels, along with a higher number of conveying wheels, boosts conveying force and doubles the speed.

- Improved Cutting Accuracy: The cut-to-length plate and cutting plate are integrated into a single unit with a thickness of 20MM, offering superior strength and stability compared to competitors’ thinner plates.

Why Choose Our Single Rebar Threading Machine Line?

- Precision: The advanced PLC control ensures that each operation is executed with pinpoint accuracy.

- Efficiency: Automated systems streamline every stage of the process, from feeding to threading and cutting, saving time and labor costs.

- Durability: High-quality materials and thoughtful design choices mean longer service life and reduced maintenance.

- Ease of Use: User-friendly interfaces and automated processes simplify operations, making it accessible even to operators with minimal training.

Conclusion:

Single Rebar Threading Equipment Machine Line is redefining industry standards with its precision, efficiency, and robust design. With a focus on innovation and customer satisfaction, we are pushing the boundaries of technological advancement to set new benchmarks for excellence. Choose our product to experience cutting-edge performance, enhanced productivity, and superior results.