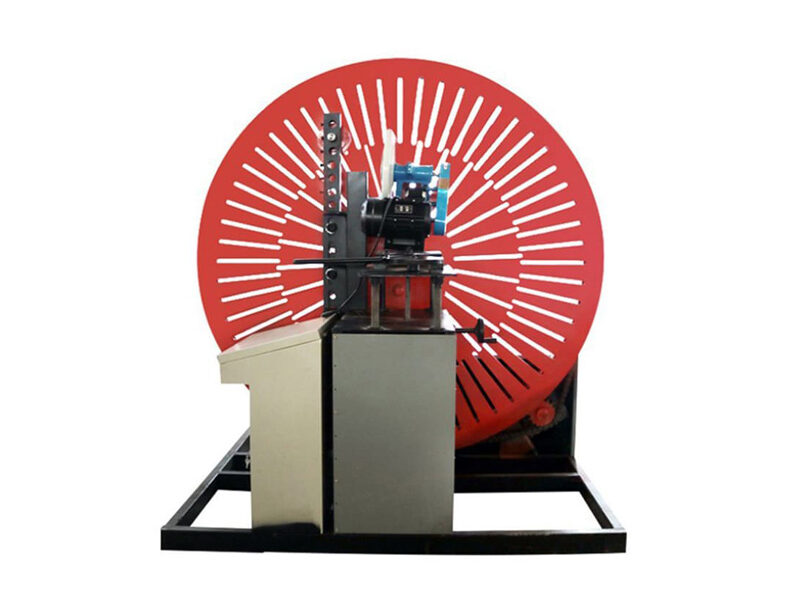

Rebar Circle Making Machine Integrated automatic welding and cutting device to achieve bending, welding and cutting in one machine

automatic completion.

| Model | WY-2200 |

| Rebar Diameter | 16-32mm |

| Circle Diameter | 800-2200mm |

| Max Bend Speed | 25000mm/Min |

| Bend Motor | 2.09kw |

| Cut Motor | 3.0kw |

| Welding Machine Model | NBC350 |

| Welding Methods | Carbon Dioxide Shielded Welding |

| Cut Methods | Diamond Saw Blade |

| Voltage | 380V(Customized) |

| Power Consumption | 7kw/h |

| Total Power | 18.75kw |

| Weight | 2000kg |

| Size | 2000*1899*2530mm |

The cutting equipment automatically cuts the remaining material completely through the cooperation of electricity and machinery.

PLC intelligent control, high-precision PLC intelligent control touch screen input, built-in encoder positioning automatic reference function, servo motor drive.

It can adapt to steel bars of different diameters, and the fully automatic bending can adapt to the welding processing of steel bars of different diameters and different lengths.

Automatically find the zero point position, making the operation more intelligent, more convenient and more time-saving.

The weld seam is full. After the welding is completed, check that the weld seam fullness meets the requirements and then manually cut the processed circles and place them in the storage rack.

It has accurate precision, fast speed and high efficiency. It can bend 150-300 steel bars in one day.

Rebar Circle Making Machine Key Advantages

1. High degree of automation, greatly reducing labor intensity.

2. PLC combined with touch screen control interface, easy to operate.

3. The whole machine is equipped with a transverse feeding device, making feeding easy.

4. Fully automatic bending to adapt to steel bars of different diameters.

5. Fully automatic welding can weld steel bars of different specifications and lengths.

6. Cutting equipment can automatically cut the remaining material completely through the cooperation of electricity and machinery.