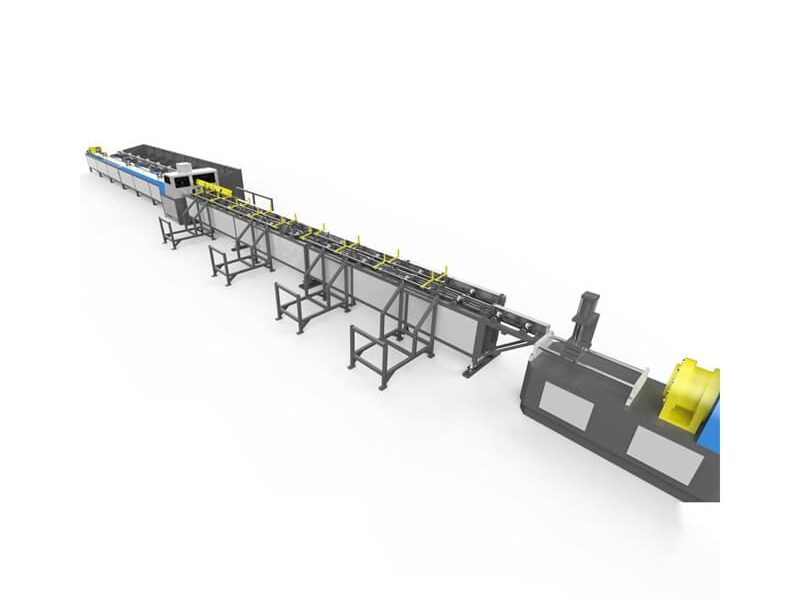

Rebar Threading Machine, also known as a Rebar Thread Rolling Machine or Rebar Straight Thread Stripping and Rolling Machine, is indispensable in the construction industry, specifically for connecting rebar. This machine stands out for its innovative design, ease of operation, and high automation, seamlessly combining rib stripping and straight thread rolling in a single process.

| Motor power | 7.5KW |

| Deceleration ratio | 1:17 |

| Spindle speed | 85 rpm |

| Rolling length | 90 mm |

| Rib stripping length | 90 mm |

| Diameter of steel bar | 16-40mm |

| Thread Angle | 60° /75° |

| TThread Pitch | 2.5mm/3.0mm |

Key Features:

- Innovative and Easy to Operate: Compact, lightweight, and user-friendly, the rebar threading machine is designed for quick and efficient use on construction sites.

- High Automation: The machine automates rib stripping and straight thread rolling in one continuous action, significantly boosting efficiency and reducing manual labor requirements.

- Precision and Durability: It delivers high-precision threads, ensuring consistent specifications across rebar connections with no exposed threads. This enhances the stability and reliability of the connection.

- Versatile: Capable of processing rebars in various diameters, the machine is suitable for a broad range of construction applications.

How It Works:

The machine processes rebar by creating robust threaded joints, often stronger than the rebar itself. These durable joints improve the overall strength and stability of construction structures. Additionally, the machine minimizes labor intensity, shortens construction timelines, and encourages a more organized and industrialized building process.

Best Practices for Operation:

To maintain optimal performance and longevity, follow these guidelines:

- Use the appropriate cooling fluid during operation.

- Keep the machine clean and regularly serviced.

- Conduct frequent inspections to ensure consistent thread quality.

Advanced Features:

With technological advancements, more efficient options like fully automatic electric threading machines are now available. These models operate with a single button press, eliminating the need for manual pressure or locking, which further enhances productivity and ease of use.